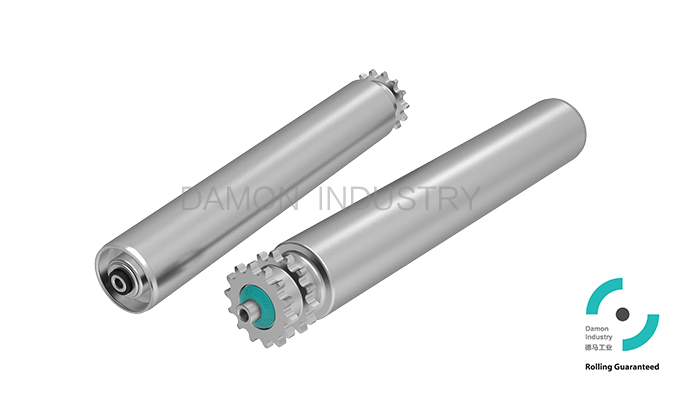

1.The polymer timing pulley is installed at the end of the roller, which makes the drive and conveying separate in the zone. The conveying is more stable and has the characteristics of high speed and low noise.

2.The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3.The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4.larger transmission capability, compact structure, tensioning-free mechanism and simple design.

5.It is more efficient without slip in conveying.

6.The T5 tooth shape design is suitable for the roller conveyor with higher versatile.

7.Its positioning is precise with the use of MDR to meet the application requirements of the load section.

8.It is suitable for clean room and other harsh environment with the use of PU synchronous belt.

9.Compared with traditional belt drive, it is waterproof (no skidding) and has the ability to work in a certain bad environment.

10.It needs no lubrication with easy maintenance.

11.Different timing belt models match the different center distance of the roller. (see the appendix)

12.Suitable for the high speed applications. Maximum speed varies with roller length and diameter. Maximum speed up to 2~3m/s. 13.Standard configuration with anti-static design surface impedance≤106 Ω.

14.Temperature range: -5℃~ +40℃. Humidity range: 30%~ 90% RH (non-condensation).

Please contact us if humidity out of this scope.

D | T | Shaft | Tube |

Steel Z/P | SS | Aluminium |

Φ50 | 1.5 | Φ12/15 | √ | √ | √ |

O——Available configuration

Remark:Φ50 rollers can be fitted with PU sleeve (2mm/3mm),PVC/PU sleeve is not anti-static.