1.The poly-vee pulley is located at the end of the roller which separates the drive area and the conveying area making the conveying smooth, high speed and low noise.

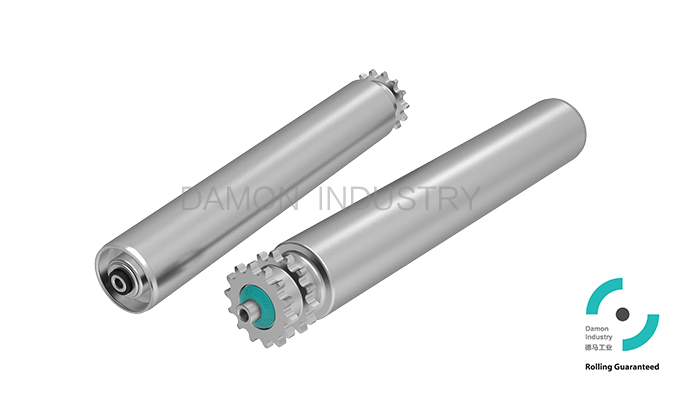

2.The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3.The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4.PJ series poly-vee. Total of 9 grooves at 2.34mm pitch.

5.Various PJ belt lengths available to suit different pitch of rollers.

6.Suitable for the high speed applications. Maximum speed varies with roller length and diameter. Maximum speed up to 2~3m/s.

7.Standard configuration with anti-static design surface impedance≤106 Ω。

8.Temperature range: -5℃ ~ +40℃.

9.Humidity range: 30%~ 90% RH (non-condensation).

Please contact us if humidity out of this scope.

D | T | Shaft | Tube |

Steel Z/P | SS | Aluminium |

Φ50 | 1.5 | 11hex,Φ10/12/15 | √ | √ | √

|

O——Available configuration

Remark: Φ50 rollers can be fitted with PU sleeve (2mm/3mm).PVC/PU sleeve is not anti-static.

Please choose the steel Poly-Vee roller when you must use 4PJ belt.