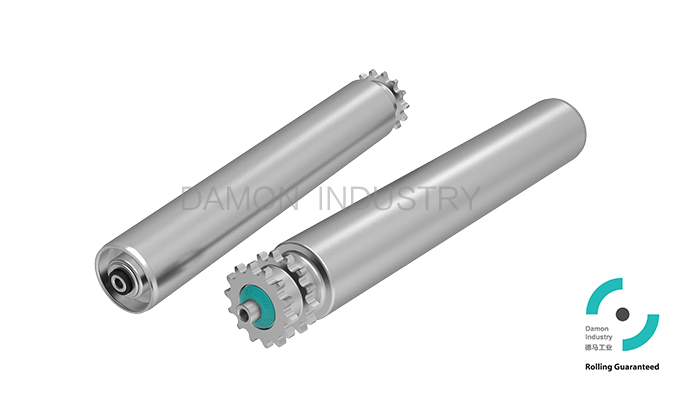

1.Welding the steel sprocket to the steel tube gives it the capacity to transmit high torque and meet the requirements for heavy duty transportation.

2.The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an

attractive, smooth and quite running roller.

3.The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4.Standard configuration with anti-static design surface impedance≤106Ω。

5.Temperature range: -5℃ ~ +40℃.

Please contact us if humidity out of this scope.

D | T | Shaft | Sprocket | A | B | C | Tube |

Steel Z/P | SS |

Φ50 | 1.5 | Φ12/15 | 08B14T | 17 | 22 | 18.5 | √ | √ |

Φ50 | 2.0 | Φ12/15 | 08B14T | 17 | 22 | 18.5 | √ |

|

| Φ60 | 2.0 | Φ12/15 | 08B14T | 17 | 22 | 18.5 | √ | √ |

Φ80 | 3.0 | Φ20 | 10B15T | 17 | 26 | 13 | √ |

|

O——Available configuration

Marks:Φ50、60 rollers can be fitted with PVC sleeve (2mm)

Φ50 rollers can be fitted with PU sleeve (2mm/3mm).

PVC/PU sleeve is not anti-static.

If steel pallets are transported, the risk of wear on roller surface is higher, please contact us in advance.