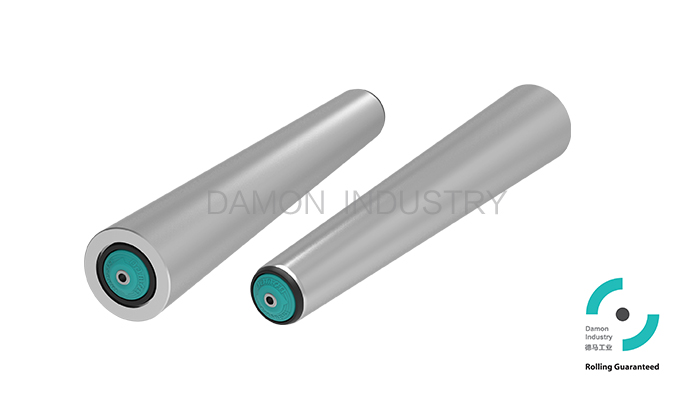

1.Based on the 2250 Series, covered with grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof.

2.In the case of sensitive to static electricity, you can choose anti-static tapered sleeve (black), surface resistance value≤106Ω

3.The poly-vee pulley is located on the head end of the roller which separates the drive area and the conveying area avoiding interference between the poly-vee belt and the conveyed goods.

4.The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

5.The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

6.ISO9982 PJ series poly-vee. Total of 9 grooves at 2.34mm pitch.

7.The duty capacity of the roller depends on the type of poly-vee belt and transmission layout. The weight of single items to be conveyed should not exceed 50kg.

8.The roller is light, easy start-up.

9.Temperature range: -5℃ ~ 40℃.

10.Humidity range: 30%~ 90% RH (non-condensation).

Please contact us if humidity out of this scope.

| D |

t |

Shaft |

WT |

D1 |

D2 |

| Φ50 |

1.5 |

11hex,Φ12/15 |

245 |

Φ55.6 |

Φ71 |

| 295 |

Φ52.5 |

Φ71 |

| 345 |

Φ55.6 |

Φ77.3 |

| 395 |

Φ52.5 |

Φ77.3 |

| 445 |

Φ55.6 |

Φ83.6 |

| 495 |

Φ52.5 |

Φ83.6 |

| 545 |

Φ55.6 |

Φ89.9 |

| 595 |

Φ52.5 |

Φ89.9 |

| 645 |

Φ55.6 |

Φ96.2 |

| 695 |

Φ52.5 |

Φ96.2 |

| 745 |

Φ55.6 |

Φ102.5 |

| 795 |

Φ52.5 |

Φ102.5 |

| 845 |

Φ55.6 |

Φ108.8 |

| 895 |

Φ52.5 |

Φ108.8 |

| 945 |

Φ55.6 |

Φ115 |

| 995 |

Φ52.5 |

Φ115 |

| 1045 |

Φ55.6 |

Φ121.3 |

| 1095 |

Φ52.5 |

Φ121.3 |

Remark: Steel Z/P and SS tubes are available.

Anti static cone sleeve (black) is available.

The taper sleeve length dimension (WT) is not accurate