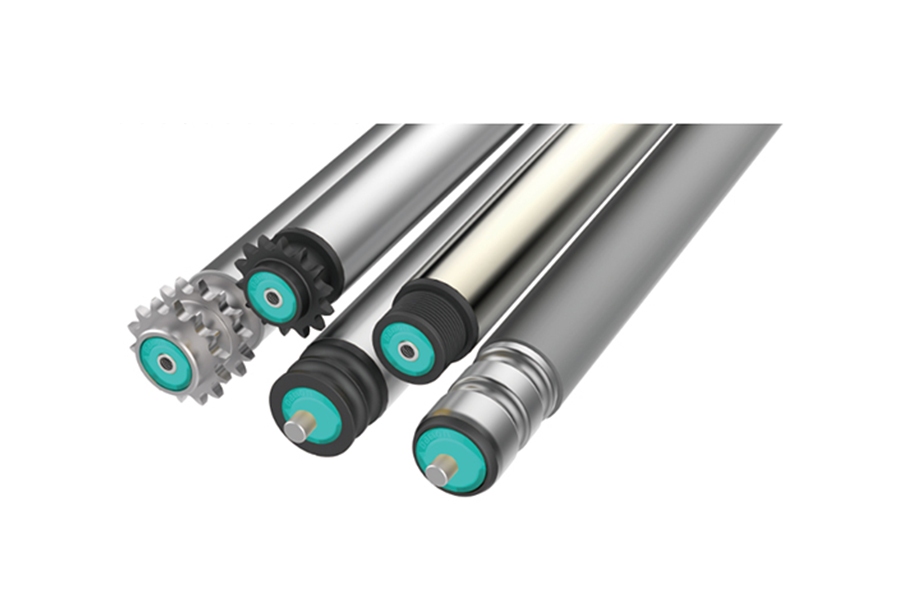

Anti-rust Performance? Accuracy ?——No, No, No, Damon Industry will settle it with one step.

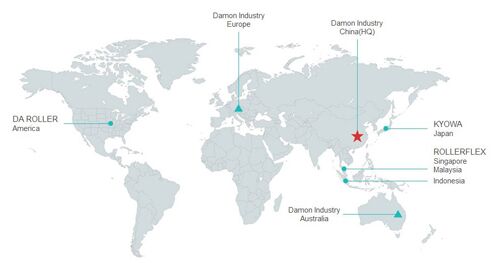

Anti-rust oil is the key, and the anti-rust oil adopted by Damon is the one that can be sprayed on the shafts at both sides of driving rollers.The ideal purpose of applying anti-rust oil is that the accuracy tolerance, installation and use standards can be met on the basis of rust protection, while, such kind of anti-rust oil adopted by Damon Industry, by plenty times of practical application, has been highly recognized by many customers in the filed of express delivery, logistics, airport and security inspection. After 20 years of highly attention on roller R&D, quality, service and details, we are capable of providing high-quality products and excellent service and solutions.

2018-06-22

More