Europe

中文

English

Europe

Welcome to Damon Industry Website

With the constant improvement of technology, logistics industry is developing faster and faster and becoming highly demanding. With the increasing demand for conveying equipment, only possessing a good set of conveying equipment can the smooth operation be guaranteed. As a roller is the essential core part of the conveyor, its quality is directly related to the operation of the whole assembly line.

As the leader of conveying industry, Damon has been exploring how to manufacture high-quality rollers and how to shorten the delivery cycle to satisfy customers' demands, and it has finally achieved preliminary results after nearly one year efforts:

With the constant improvement of technology, logistics industry is developing faster and faster and becoming highly demanding. With the increasing demand for conveying equipment, only possessing a good set of conveying equipment can the smooth operation be guaranteed. As a roller is the essential core part of the conveyor, its quality is directly related to the operation of the whole assembly line.

As the leader of conveying industry, Damon has been exploring how to manufacture high-quality rollers and how to shorten the delivery cycle to satisfy customers' demands, and it has finally achieved preliminary results after nearly one year efforts:

I. Lean Project Promotion

In 2017, the company leaders proposed lean production idea. Through discussion, they decided to firstly simplify the production and processing procedures to reduce production costs and improve product precision. To achieve the goal, we have optimized the processing procedures of belt conveyor roller and tension roller series product through equipment upgrading, which achieved clamping and completion of four procedures only with one operation, with a production capacity increase of 45%. In addition, such optimization not only reduced the production costs, but also greatly improved product quality and accuracy. And each indicator rises steadily, product run out is limited within the standard range and the precision of products gets improved, which further satisfy the high-profile clients' requirements for products. H6 standard precision products have been widely used in a large international airport project in China.

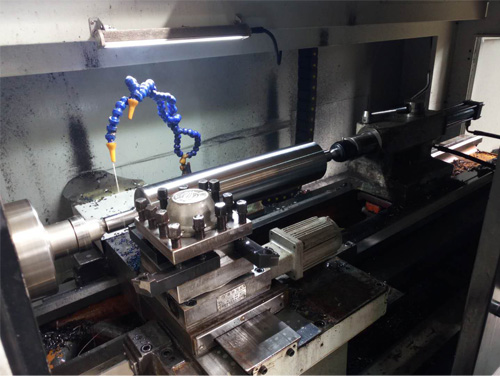

II. Equipment Optimization

To improve equipment automation, product quality, production efficiency and market competitiveness, our company attaches great importance to the investment of automatic equipment. In 2017, our company bought two advanced automatic double-head boring machines successively. With the boring machines put into use, the control for product concentricity got guaranteed, which solved the phenomenon of bearing jam caused by the inconsistent concentricity of bearing holes at both ends and effectively ensured the service life of internal bearing-type tension roller.

With the introduction of the world's top fast blanking equipment RSA, the blanking production capacity speed was lifted, which solved the problem of the lag of the front blanking procedure due to the rapid growth of orders and also effectively guaranteed the delivery cycle and product precision, with blanking tolerance precision within ±0.25mm, and saved costs of materials and labor.

In August 2018, we will introduce a custom-built machine - automatic milling machine. Introducing and using this machine will greatly improve the rough processing capacity of thebelt conveyor roller. The production capacity is expected to increase by 50% and the problem of shortage of personnel can be effectively solved.

Through our unremitting efforts, our products have an edge over our competitors in market competitiveness, and we believe our customer satisfaction will be further improved.