Europe

中文

English

Europe

Welcome to Damon Industry Website

This is not just a traditional Conveyor Roller – it is the "DNA" of logistics conveyor equipment.

We redefine logistics conveying efficiency with "Stability + Intelligence + Energy Saving + Cost Effectiveness".

Exclusive Preview: Damon Industry will showcase four core solutions at LogiMAT China 2025, bringing efficient, intelligent, and reliable Conveyor Roller technology to the logistics conveying sector:

1. "Granite" High-Strength Steel Conveyor Roller Solution

The Tube is constructed from high-strength steel material, offering yield strength and tensile strength that are 2 times and 1.5 times greater, respectively, than conventional Q235B Tube material. This allows for a lighter-weight Tube while maintaining equivalent Load Capacity. Taking the Φ76 pallet Conveyor Roller as an example, Damon Industry's use of high-strength steel and structural optimization enables a weight reduction of nearly 30%. In application, even assuming a conservative daily energy saving of 0.05 kWh per Conveyor Roller, a site utilizing 2,000 Conveyor Rollers can save 100 kWh daily, amounting to over 30,000 kWh annually, significantly reducing operational energy consumption costs.

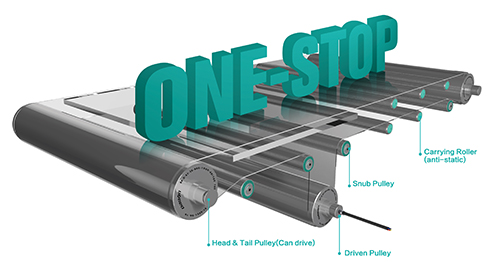

2. "Complete" Belt Conveyor Pulley One Station Solution

Damon Industry utilizes innovative permanent magnet synchronous, oil-free cooling drive technology to create high energy-efficiency, naturally cooled, and eco-friendly Motor-Drive Rollers for belt conveyors. Concurrently, through high-strength welding and precision machining processes, we provide standardized, serialized, and high-strength Belt Conveyor Pulley products. Whether you require Motor-Drive Rollers, Carrying Rollers, Head & Tail Pulleys, Driven Pulleys, or Snub Pulleys, we offer a comprehensive Belt Conveyor Pulley One Station Solution.

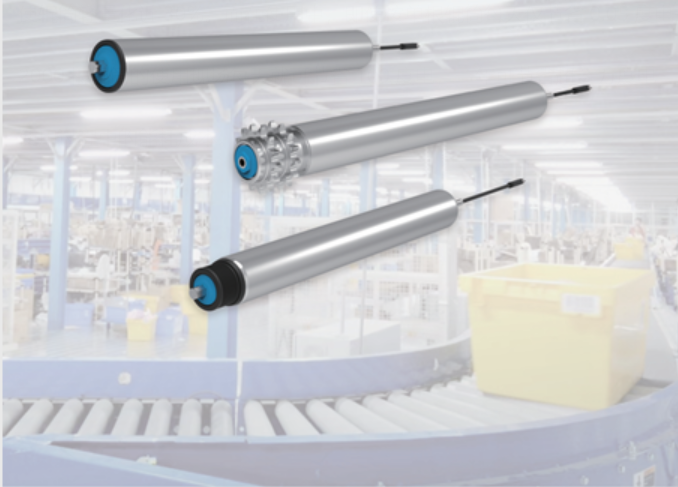

3. "Smart Brain" Highly Intelligent Motor-Drive Roller Solution

Damon Industry and CONVEYLINX series drive cards feature built-in intelligent conveying and program customization module functions. This reduces the workload for electrical engineers, shortens on-site debugging time, lowers labor costs, and enhances the versatility of customer on-site applications. Its data self-backup function enables users to perform rapid maintenance in the field, minimizing losses associated with equcommunication protocols, including Profinet, Ethernet-IP, Modbus TCP/IP, and CC-Link. Compared to conventional switching signal control drive cards, this approach significantly reduces the user's overall costs, particularly for large-scale projects.

4. "Beyond" DMD Domestic Motor-Drive Roller Solution

Employing a novel motor structure design to maximize motor efficiency. Utilizing an external rotor direct drive scheme, the Load Capacity is increased by up to 57% compared to gear reduction structures. It incorporates a 17-bit absolute encoder for precise servo control. The design of the servo direct-drive external rotor motor enables the Conveyor Roller to maintain substantial torque output even at speeds of 2.0 m/s.

Preview Ends Here!

More Conveyor Roller product solutions are exclusively available to on-site visitors. April 24-26, Shenzhen Convention and Exhibition Center H7-C17.

Scan the code now to reserve your "free admission"!