Europe

中文

English

Europe

Welcome to Damon Industry Website

With the development of the Belt and Road Initiative, Chinese companies are actively expanding into the Southeast Asian market. As we all know, Thailand is a tropical country by the sea, rich in resources such as green vegetables, seafood, fruits/dried fruits, and canned goods. Damon Industry lightweight tapered rollers are fortunate to contribute to the automation of intralogistics in Thailand's food industry.

This project involves transporting goods weighing between 1 to 50 kg from the second floor to the first floor, with a floor height of 6 meters. To save space, reduce costs, and meet the efficiency requirements of the conveyor system, our client chose a spiral conveyor solution for their Thai end user. The end user was very satisfied with the solution but requested a gravity-driven, non-powered spiral roller conveyor to further reduce equipment costs and save energy. This solution indeed has low initial costs, low energy consumption, and almost no usage or maintenance costs. However, the biggest challenge lies in ensuring that goods weighing less than 1 kg can slide down smoothly. Will there be any blockages during the descent? If blockages occur, it could reduce efficiency or even damage the goods, which is the key to the project's success.

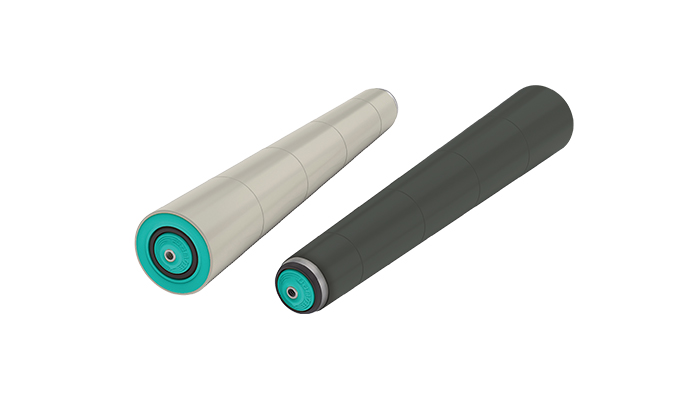

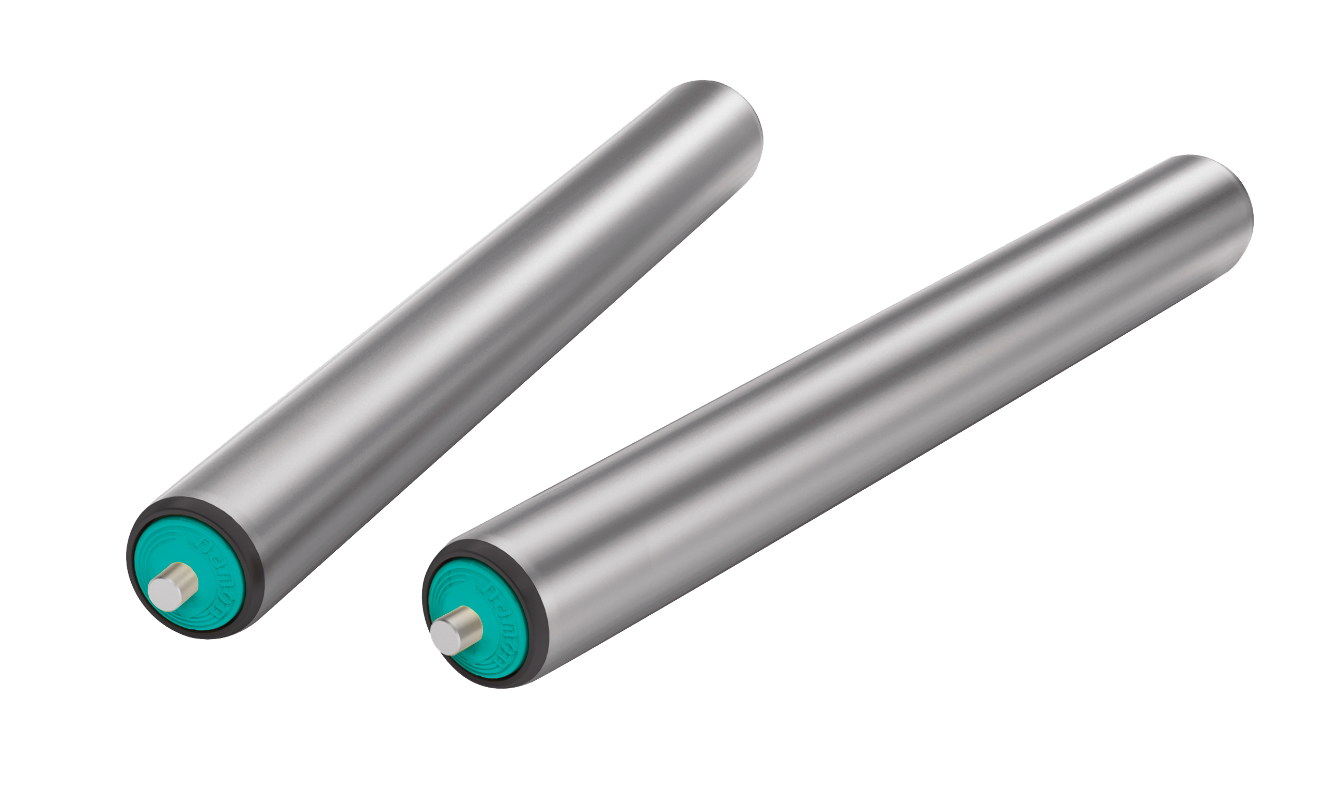

After understanding the key requirements of the project, the team from Damon Industry worked closely with the client to discuss detailed application specifics. Damon Industry unique lightweight roller solution was proposed. This roller requires only 12g of starting force to begin rotating when static. Thanks to the high-quality steel tubes, the uniquely designed lightweight bearings, and excellent manufacturing, the rollers are fully capable of meeting the conveyor's requirements.

To ensure accuracy, the client first conducted prototype testing. The results fully met the project's requirement that goods as light as 1 kg (1000 g) should slide down smoothly relying on gravity. This success gave the client strong confidence in the entire project. Currently, a total of 42 sets of equipment are in operation at the

end user’s site, performing reliably and receiving positive feedback and recognition from the client.

Damon Industry lightweight tapered rollers are perfectly suited for the smooth automation of spiral conveyors. They help businesses optimize cargo handling, save space and labor resources, increase production capacity, and improve operational efficiency while reducing costs. This makes them a solid foundation for intelligent manufacturing. Furthermore, Damon Industry lightweight rollers have now exceeded 3 million units, serving high-speed sorting systems at global logistics centers such as Amazon and DHL. This is our way of giving back to our customers for their trust and support!