Europe

中文

English

Europe

Welcome to Damon Industry Website

The 12th Global Intelligent Logistics Industry Development Conference and 2024 Global Logistics Equipment Entrepreneurs Annual Meeting, organized by Logistics Technology and Application Magazine, successfully concluded on December 5-6, 2024, in Suzhou. Zhejiang Damon Industrial Equipment Co., Ltd., a leading enterprise in the industry, was honored with the "Intelligent Logistics Industry Technology Innovation Award" at this conference by virtue of its many years of continuous innovation and dedicated efforts in the field of logistics equipment components.

Mr. Jin Chunhui, Deputy General Manager of Damon Industry, and Mr. Wang Zhaoyan, Domestic Sales Director, were invited to attend the event and accepted the award. Mr. Jin stated: "This honor is a recognition of our team's long-term efforts. The rapid development of logistics automation in the Chinese market has also presented new challenges to logistics equipment enterprises. As a core component of warehousing and logistics, conveyor roller manufacturers naturally have to keep abreast of the times and develop corresponding products according to the needs of customer's industry. High-strength steel conveyor rollers are one such product."

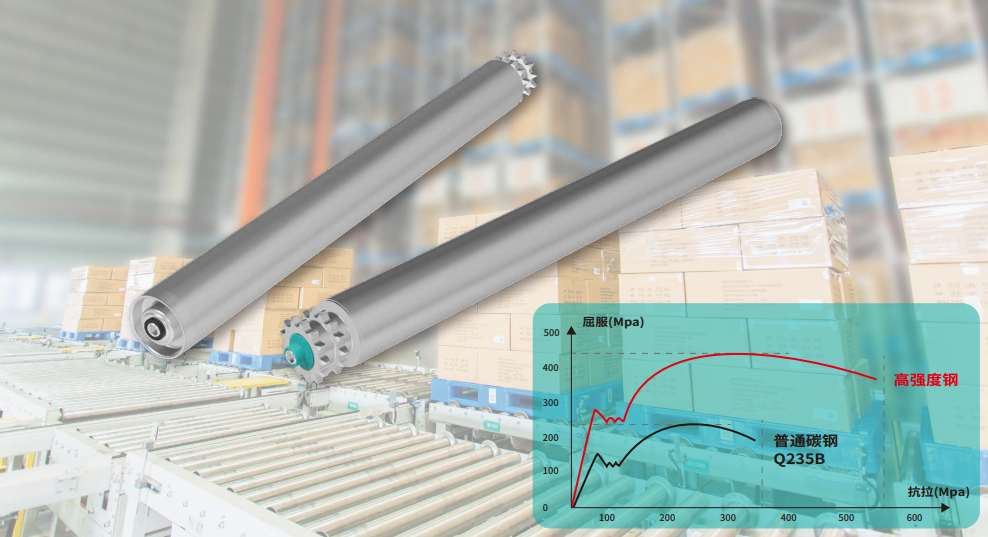

High-strength steel, as the name suggests, is a type of steel with higher tensile strength and yield strength. It has been widely used in aviation manufacturing, automobile manufacturing, high-rise buildings, and other fields. These fields share a common need: lightweighting.

With the constant promotion of global energy conservation and emission reduction strategies, along with the rapid development of the logistics equipment industry, higher demands have been placed on the lightweighting of logistics conveying equipment. Conveyor rollers, as one of the key components of logistics conveying equipment, are numerous and constantly in operation, making them significant energy consumers. Currently, Q235 steel is commonly used for the tube, and it has long been the default option in the industry. However, in order to find a better option, Damon Industry keenly recognized that this is an important part of the lightweight design of conveying equipment, and thus innovatively applied high-strength steel to the conveyor roller field.

After repeated comparison, screening, and verification of various materials with steel manufacturers, Damon Industry selected a high-strength steel whose yield strength and tensile strength are 2 times and 1.5 times that of the conventional tube material Q235B, respectively. Therefore, a lighter tube can be used to achieve the same load-carrying capacity. Taking the Φ76 pallet conveyor roller as an example, Damon Industry, by adopting high-strength steel and structural optimization, can reduce the weight of the conveyor roller by nearly 30%. In use, even if a single conveyor roller saves only 0.05 kWh of electricity per day, a site with 2,000 conveyor rollers can save 100 kWh of electricity per day, resulting in savings of over 30,000 kWh of electricity per year. This significantly reduces energy consumption costs during the process of using.

Taking the existing product series as a platform, Damon Industry has comprehensively explored and upgraded the high-strength steel tube across the commonly used diameter series. The main body shape and installation conditions remain consistent with the standard carbon steel models, ensuring seamless integration into both the design selection of new projects and the spare parts for projects already in operation. In addition to the lightweight design of the product itself, the structure has been optimized in several aspects, further improving the cost-effectiveness of the conveyor roller products.