Europe

中文

English

Europe

Welcome to Damon Industry Website

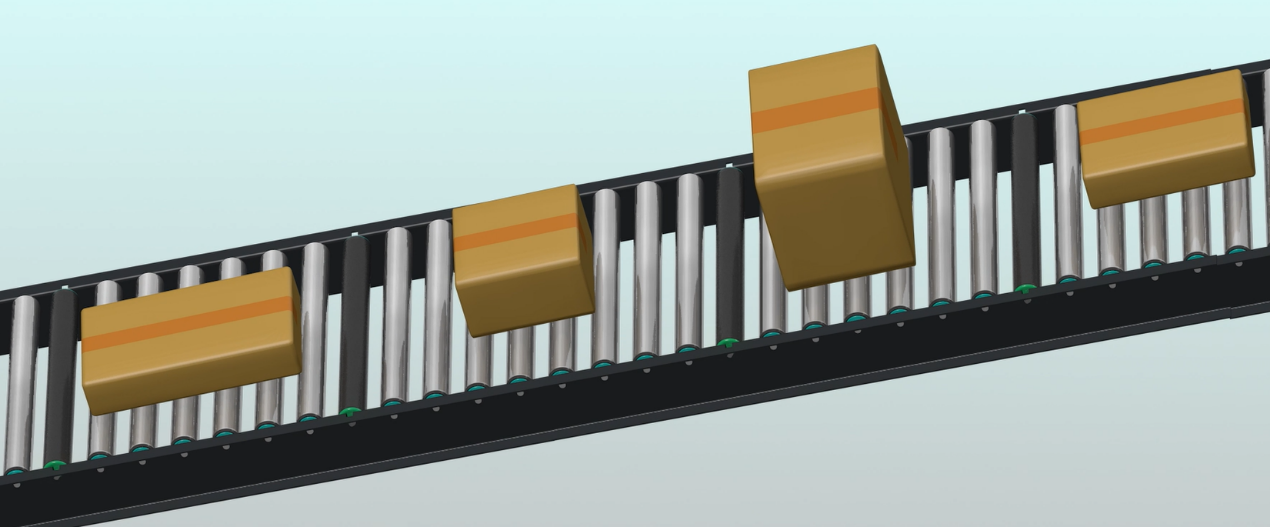

In today's conveying and sorting environments across various industries, there is an increasing focus on space-saving, cost-saving, energy-saving, and emissions reduction. Unpowered glides with a certain angle of inclination have become the preferred solution for sorting goods.

Issues arising from unpowered gravity roller glides without a "safety guard" include challenges in selecting slide angles and ensuring precise speed control for goods of different shapes, sizes, and weights. Excessive sliding speeds can cause goods to tumble or forcefully eject from the slide chute, leading to uncontrolled movement and potential damage. This poses a significant risk to the integrity and safety of transported goods, resulting in substantial losses for customers. Unpredictable sliding states increase the risk of accidents and injuries to personnel. Inability to anticipate and control the movement of goods during transport may lead to collisions, entanglements, or other hazardous incidents, thereby reducing overall operational efficiency.

In response to these challenges, Damon Industry recommends implementing a flexible speed controller solution, known as the damping roller, tailored to specific applications. The damping roller is a specialized functional roller utilized in passive sliding tracks to counteract gravitational acceleration and ensure the cargo's speed remains within a safe range.

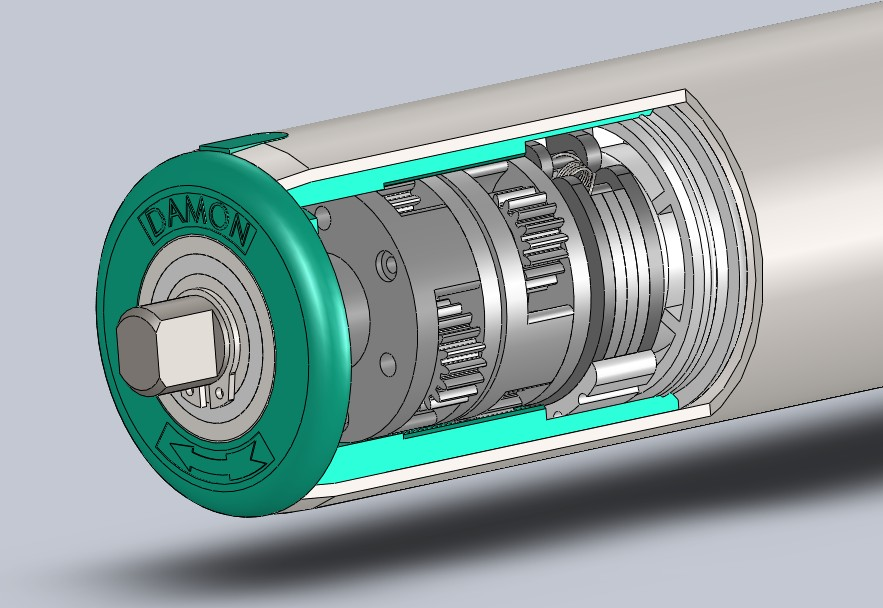

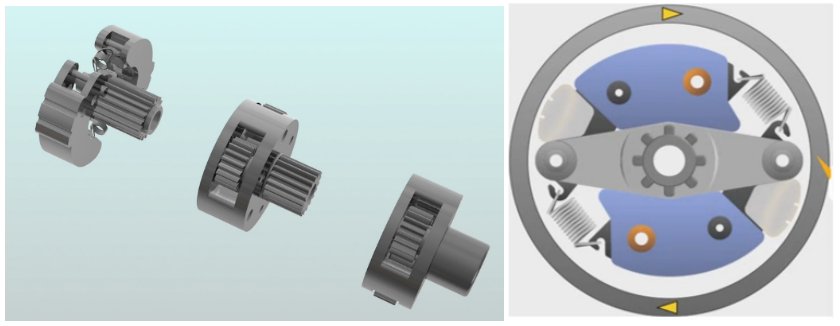

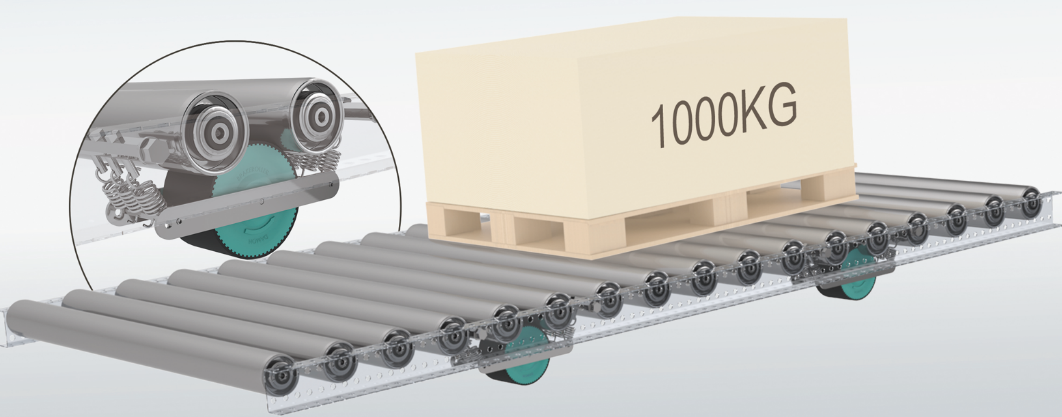

The damping roller consists of multi-stage planetary gears and friction components. During operation, the friction blocks rub against the cylinder wall due to centrifugal force. The heavier the cargo, the greater the generated friction force. When passing through the damping roller, the cargo experiences resistance, resulting in reduced sliding speed. In essence, the damping roller aims to slow down fast-sliding cargo, ensuring safe conveyance at a lower speed, enabling smooth arrival at the bottom position. This prevents damage to equipment, cargo, and personnel caused by excessive speed while avoiding transportation jams resulting from excessively slow conveyance speeds.

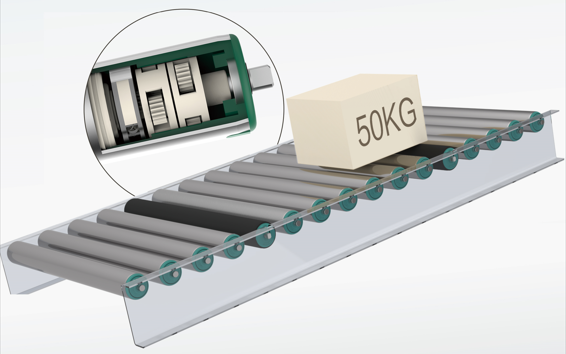

Safe and stable speed control

Damon Industry’s damping rollers are not only suitable for light-load conveyance types ranging from 10-100kg but also for medium-load conveyance types ranging from 200-1500kg. With their flexible speed control design, they autonomously adjust based on the weight and sliding speed of the cargo, generating adaptive and dynamically changing resistance. Whether it's a picking-style slide for small items or a dynamic storage slide for heavy-duty pallets, the damping rollers ensure safe and stable downward conveyance at an appropriate speed.

Green transportation with zero energy consumption

Damon Industry's damping roller is a critical component of a zero-energy gravity-based conveying solution. With this key component, it becomes possible to safely and stably convey your goods in elevated positions by harnessing the force of gravity on the roller track. By utilizing the weight of the cargo for transportation, it eliminates the need for electrical control design, enabling customers to achieve a green, safe, and cost-effective conveyance with "zero" energy consumption.

Reasonable cost and convenient maintenance

With a purely mechanical structure, Damon Industry's damping roller offers a reasonable upfront procurement cost. Its zero-energy consumption during operation leads to very low usage costs. Furthermore, its simple structure allows for easy installation and convenient long-term maintenance. The extended service life and component replacement cycles significantly reduce both the manpower and economic costs associated with subsequent maintenance.

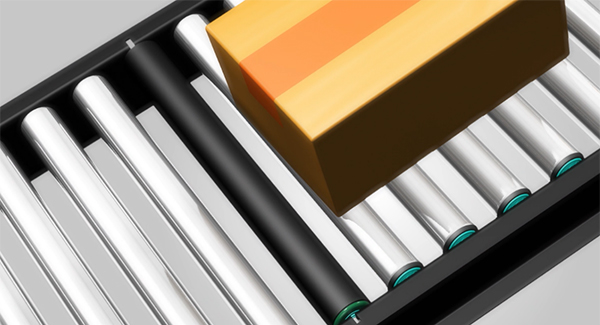

During the actual installation of the damping roller, it is recommended to position the roller surface 1-2mm higher than that of the passive roller to ensure effective speed control. Applying a PU coating on the surface of the damping roller is advised to maintain consistency in the frame hole positions. This surface treatment not only increases friction between the roller surface and the conveyed material but also enables smoother and safer downward sliding of the cargo while protecting the cargo's surface from damage.

Damon Industry's PU-coated damping rollers have been successfully operating in projects with internationally renowned express delivery companies for over two years. They have undergone rigorous testing by overseas express e-commerce clients, proving their reliability and performance.

Damon Industry's damping rollers have gained widespread application in various industries, including commercial distribution, express delivery, and more. Companies such as SF Express, JD.com, DHL, Tesla, Haitian, and China National Pharmaceutical Group have chosen Damon Industry damping rollers. The years of stable and reliable operation have garnered positive evaluations from our esteemed customers.