Europe

中文

English

Europe

Welcome to Damon Industry Website

As the name suggests, high-strength steel is a type of steel with high tensile and yield strength. It has been widely used in fields such as aerospace and automotive manufacturing and high-rise building construction. These fields share a common requirement: lightweight design.

With the continuous advancement of global energy-saving and emission-reduction strategies, along with the rapid development of the logistics equipment industry, higher challenges have been posed for the lightweight design of logistics transportation equipment. Lightweight design can reduce the weight of logistics equipment, thereby lowering energy consumption and costs during transport and use. This aligns with the development trend of green logistics, offering greater flexibility and mobility, enabling quicker responses to system demands, and enhancing transportation efficiency. However, traditional logistics transportation equipment often faces issues such as excessive weight and high energy consumption, which limit its further development and application. Therefore, exploring lightweight technology for logistics transportation equipment is of great significance for improving the overall efficiency of logistics systems.

Roller components, as one of the key parts of logistics transportation equipment, exist in large quantities and operate continuously, making them significant energy-consuming components. Currently, the commonly used material for roller bodies is Q235, which has long been the industry standard. However, pursuing better alternatives, Damon Industry keenly recognized that this component plays a crucial role in lightweight design for transportation equipment. As a result, they innovatively applied high-strength steel to the roller sector.

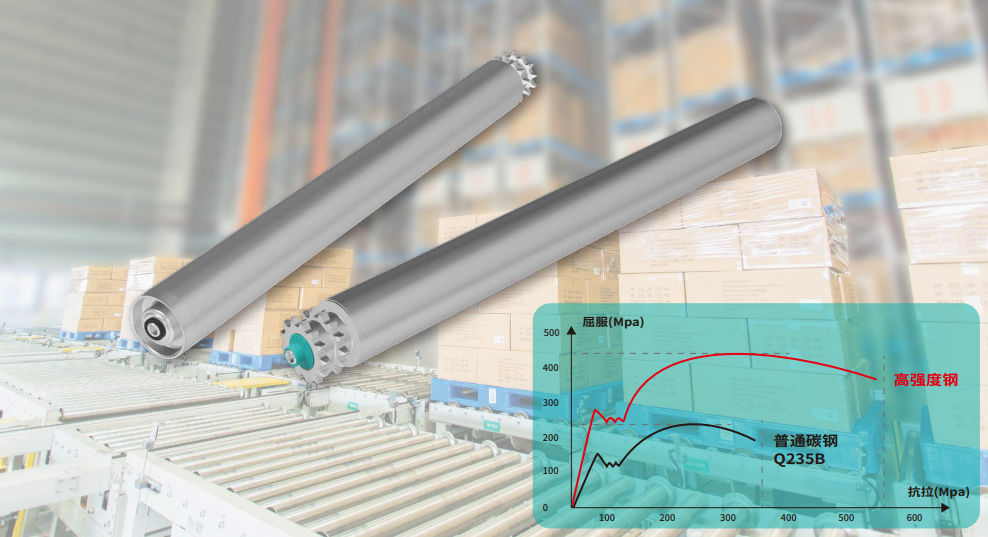

After repeated comparisons, screening, and validation of various materials with steel manufacturers, Damon Industry selected high-strength steel with yield and tensile strengths that are double and 1.5 times that of the conventional Q235B material, respectively. This allows for the use of lighter tubing while maintaining the same load-bearing capacity.

For example, in the case of a Φ76 pallet-type roller, Damon Industry achieved a nearly 30% reduction in weight by using high-strength steel and optimizing the structure. In operation, even if each roller saves only 0.05 kWh of electricity per day, a site using 2,000 rollers could save 100 kWh daily. This translates to more than 30,000 kWh saved annually, significantly reducing energy consumption costs during use.

Damon Industry has leveraged its existing product series as a platform to comprehensively expand and upgrade the use of high-strength steel roller bodies across commonly used diameter series. These upgraded rollers maintain the same main shape and installation conditions as standard carbon steel versions, allowing seamless integration for both new project designs and spare parts in ongoing projects. In addition to the lightweight design of the product itself, multiple structural optimizations have been made to further enhance the cost-effectiveness of the roller products.

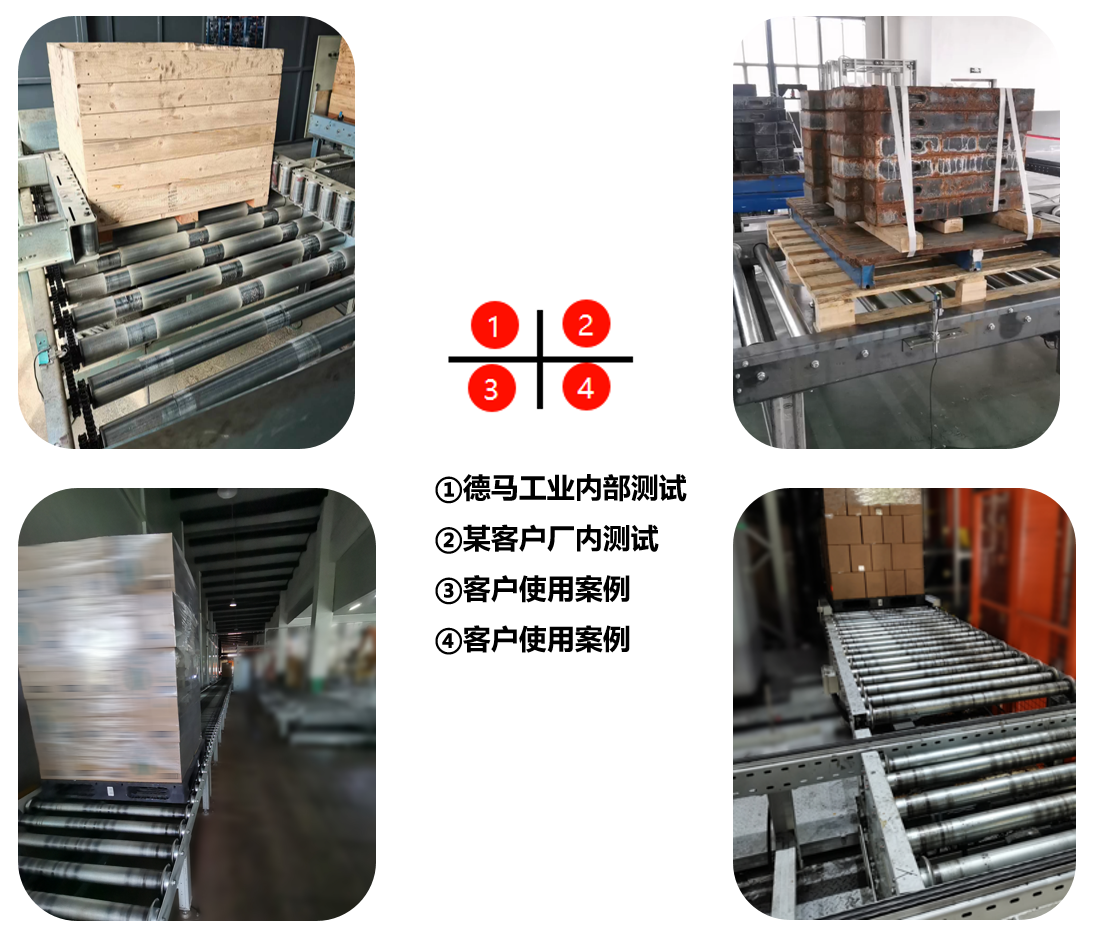

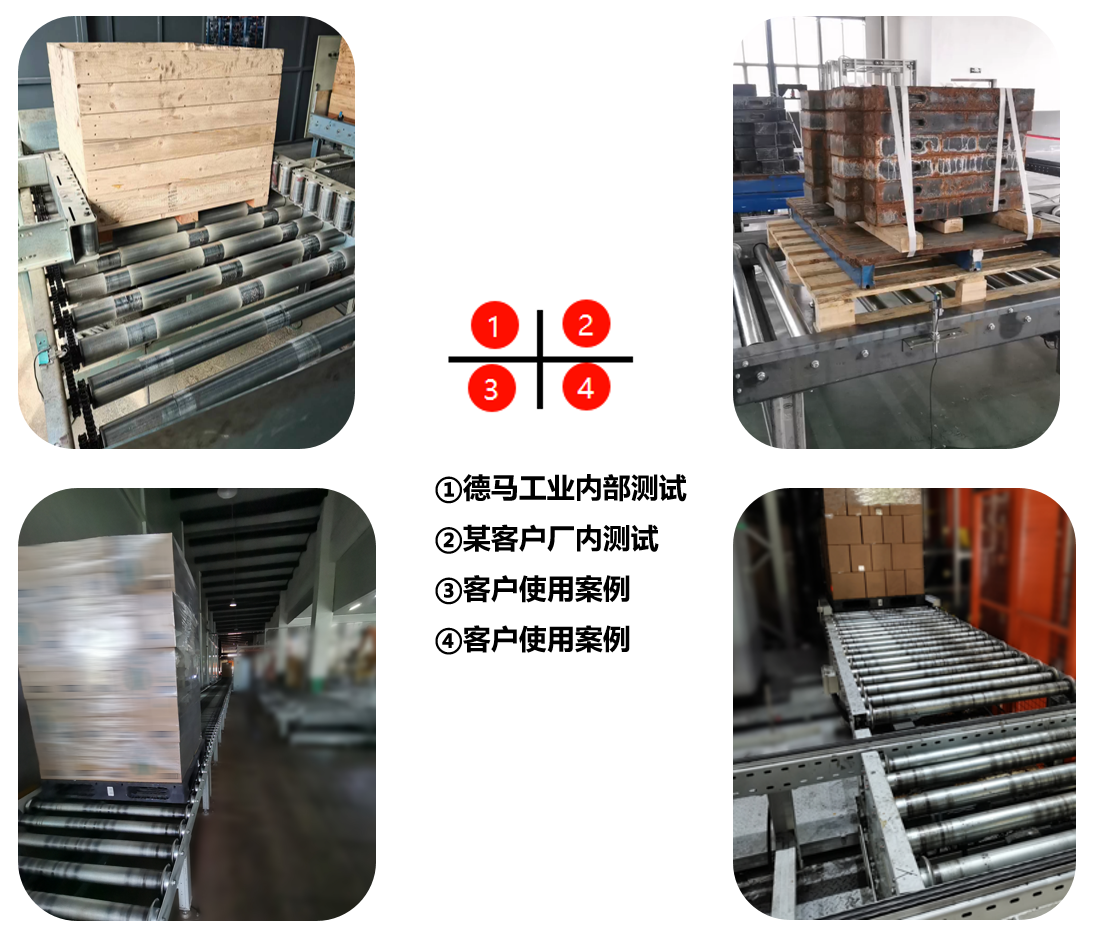

Before launching the product, Damon Industry conducted over one million operational tests in its in-house R&D testing facility. Additionally, reliability validation was carried out at client sites to ensure that the products provided to customers are high-quality, stable, and reliable.

Since the product was launched in the first half of this year, it has been applied in various fields, including paper manufacturing, automotive, food and cold chain industry, filling and packaging, and e-commerce. The total number of units in use has exceeded 10,000, and the current usage conditions are stable, with positive feedback from customers.

If you would like to learn more, come visit us at the Shanghai New International Expo Center, Hall W3, B2-1, from November 5th to 8th for a face-to-face discussion regarding our products. We will also have many practical products, innovative solutions, and fun activities waiting for you at the exhibition!