Europe

中文

English

Europe

Welcome to Damon Industry Website

In the post-epidemic era, the economy is gradually recovering, and all industries are ready to take off, as we can notice that the demand for logistics and supply chains is increasing. In the past three years of the epidemic, Damon Industry has never stopped. We keep collecting, accumulating, and accurately understanding the market and customers' needs, and targeting to customize the development and production of intelligent, networked, flexible, and low-carbon roller products for conveying, to provide customers with more suitable, more economical and more efficient one-stop roller solutions for conveying.

Hannover LET Guangzhou Logistics Exhibition will be held from May 18-20 at the Canton Fair Complex. We invite you to pre-register at our booth in Hall 19.1, Booth F20 to discuss roller solutions for conveying.

Electric cam roller for right-angle loader

As a key element of the lifting mechanism of the right-angle lifting machine, our motorized cam roller is a highly integrated reciprocating mechanism and represent a powerful element in the lifting process, which fully empowers the customer to design and manufacture the lifting machine:

When the electric cam roller rotates at 90 degrees, the platform can be switched, and the efficiency of the equipment can be improved, reaching 2000+/ hour at a 50% cargo transfer rate.

The drive and actuator are integrated, with a compact structure, and a light and thin design, at a minimum of 180mm.

Double cam plate design, separately control different platform lifting, and the vertical position of the goods during the shifting process remains unchanged, which is convenient for installation and debugging while ensuring product safety.

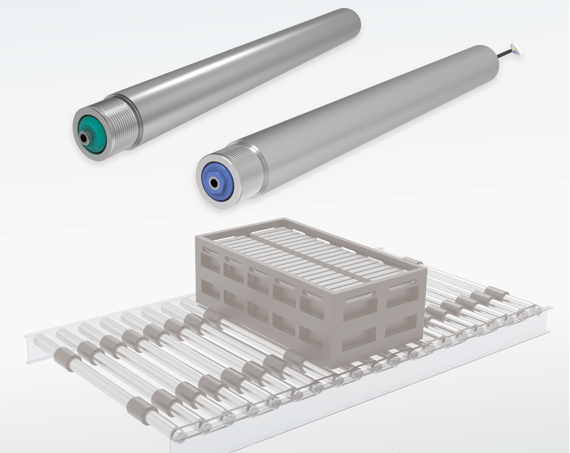

The φ 60 box-type electric roller

For medium and heavy load conveying and zero-pressure accumulation conveying, Damon Industry has realized the local assembly of Φ60 bin type electric roller, which can provide better service and technical support to customers while shortening the delivery time. Φ60 bin type electric roller will meet more application needs of customers with its advantages of large load, low energy consumption, high stability, and intelligence.

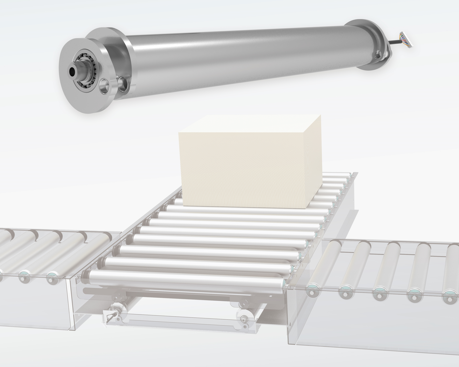

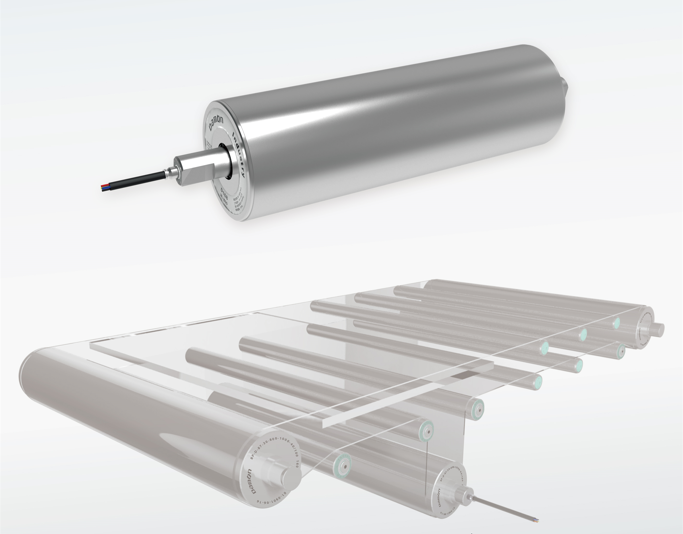

One-stop solution for belt conveyor rollers

In addition to high-strength belt rollers, we have also developed a new generation of electric belt rollers with new motor technology to provide you with a one-stop solution for belt conveyor rollers. The new "Electric Roller for Belt Conveyor" has the following advantages:

1. Energy saving and emission reduction: compared with the traditional belt electric roller or ordinary motor, energy saving reaches 20-40%, and the energy saving rate is different under different equipment working conditions.

2. First-class energy efficiency: the energy efficiency is above 95%, and the stator is not required to provide induction electricity, which is less than the loss of ordinary motors. The no-load current is small, only reaching one-tenth of the rated current, while the current of the traditional belt electric roller or ordinary motor reaches one-third when it is no-load.

3. Stable output: during operation, the energy efficiency value can remain unchanged when the load changes.

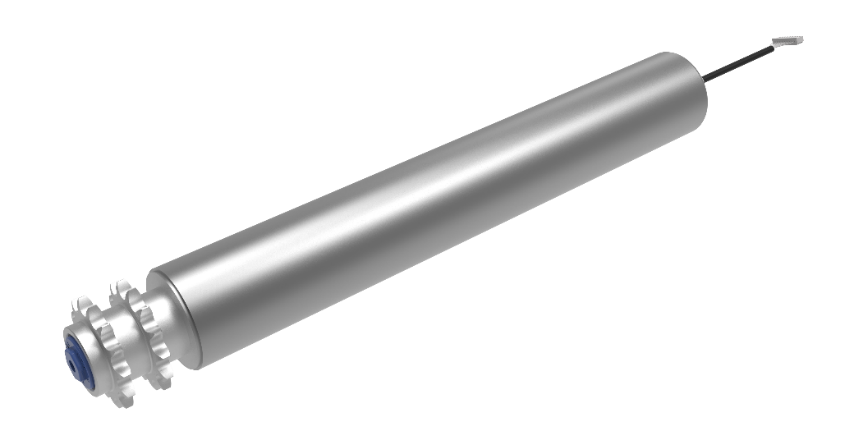

Medium-load multi-wedge pulley roller conveying solution

With the rapid development of the logistics system, as the most widely used box conveyor, multi-wedge pulley roller is also facing new requirements and challenges such as improving load capacity, and adapting to more industry characteristics and different application environments. Our medium-duty multi-wedge pulley rollers are based on conventional multi-wedge pulley rollers, presenting the pulleys and components in a steel combination and upgrading the pulleys to work with wider multi-wedge belts, resulting in a breakthrough in the conveyor load capacity of multi-wedge pulley rollers:

1. Belt pulley upgrade: steel belt pulley and steel pipe are welded, which is more reliable and eliminates the risk of loosening.

2. Load upgrade: 11 grooves instead of 9 grooves, a 5PJ V-ribbed belt, improving greatly the torque transmission capacity.

3. Applicable to upgrade: the scope of the applicable environment is wider, and it can be applied to high, low and low humidity environments.

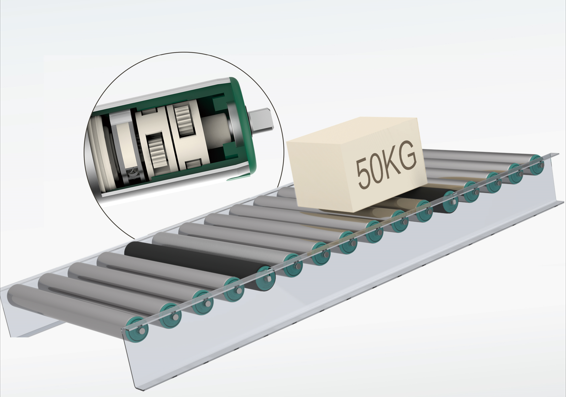

Flexible gravity speed controller

The 50-diameter light-duty built-in damping roller can reduce the speed of objects of different weights in a wide range of angles, offset their gravity acceleration, provide adaptive damping force, and make the conveying speed of gravity slideway stable and controllable. It has the advantages of zero energy consumption and no maintenance. At present, it has been widely used in DHL, SF, EMS, Jordan and other projects.