Europe

中文

English

Europe

Welcome to Damon Industry Website

Our family has a common name -Damon rollers. Although our conveying roller family has a long history, there are still some Gods who can't tell us apart.

Next, let me give you an introduction.

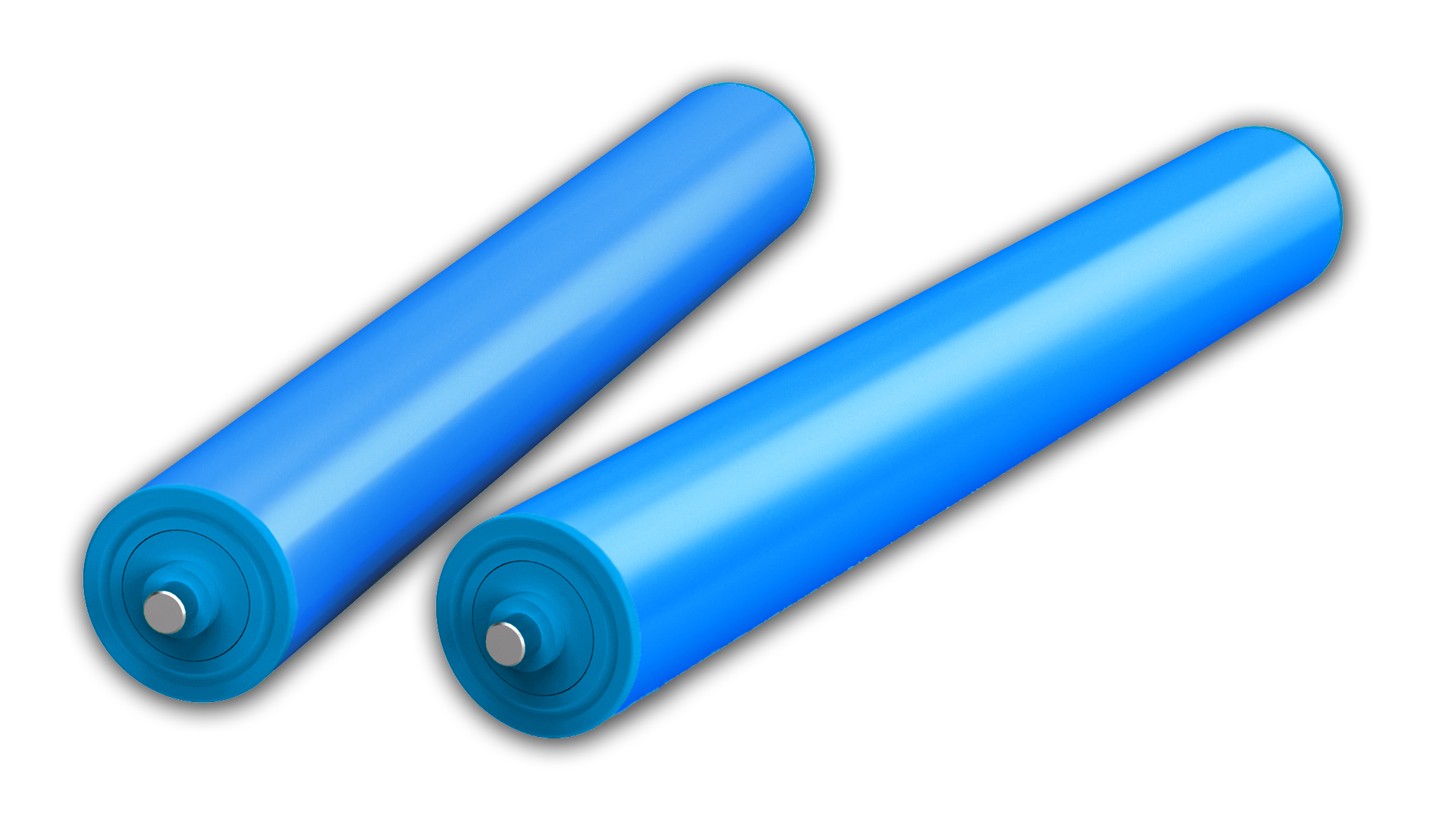

First of all, our 1900 series appeared. Generally speaking, the 1900 series is an "alien", which is different from other metal coats for conveying rollers. It is made of PVC engineering plastic, and it is very beautiful. Not only has a great appearance, but also has a flexible and light body shape, which is suitable for light load conveying. Special plastic ball bearings are used. The inner and outer rings of the bearings are made of polyurethane (POM) and the balls are made of stainless steel. Due to the different coating, the 1900 series can only be used in -5℃ to +40℃ environment. Like them, we have our 1200 series.

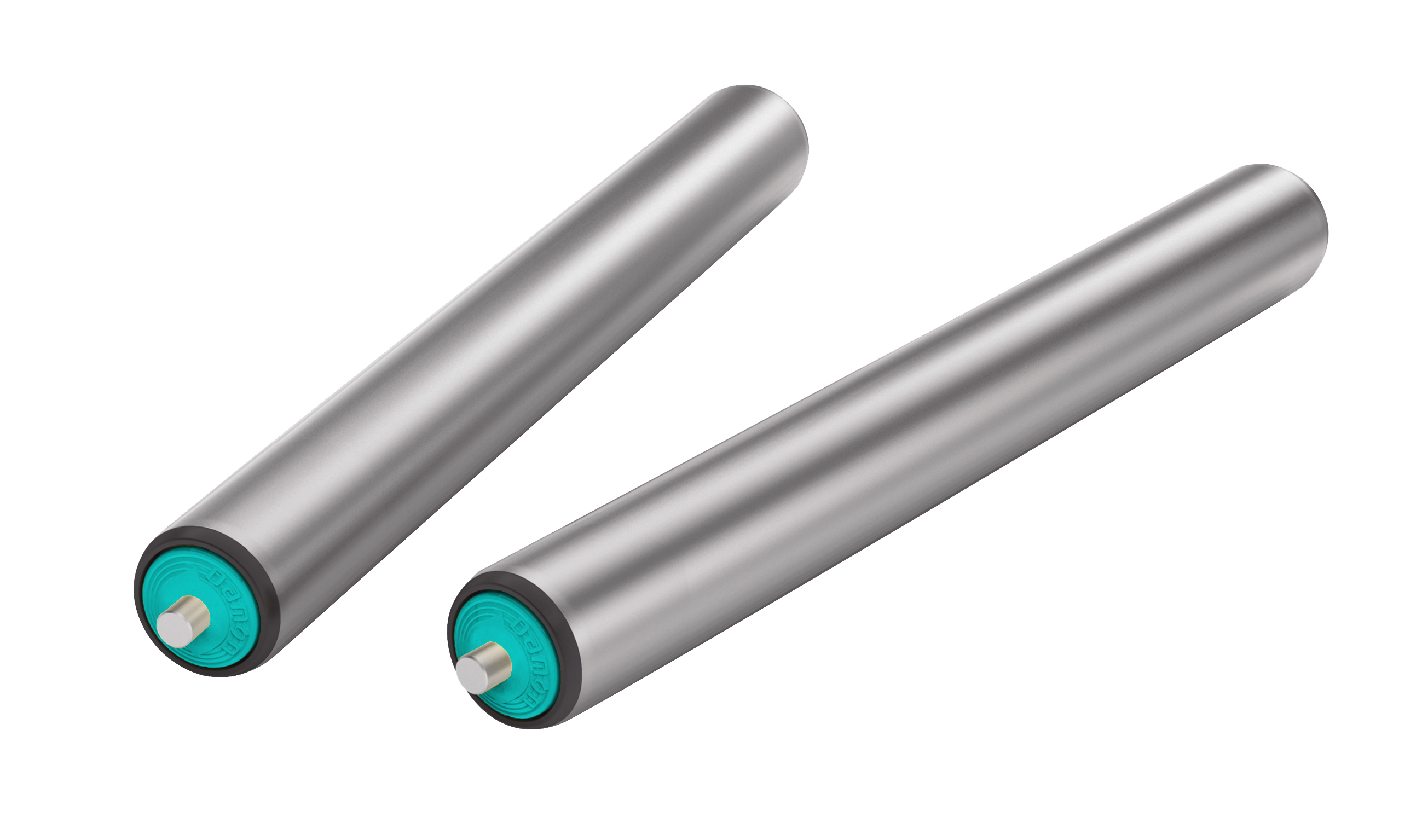

Compared with the 1900 series, the 1200 series roller are beautiful and silent. Although the head and tail are designed with plastic inner and outer coats, the adaptive temperature is the same as that of the 1900 series, but because of this, it is more silent during operation. Meet our beautiful and silent product. The 1200 series is very popular for box-type conveyors. On many occasions, you can see the green color of Damon. The design of the plastic end covers, to a certain extent, prevents the damage of the bearings caused by dust and water. They can also be equipped with different bearings according to the application conditions to meet various requirements such as light sliding conveying. Very silent, when operating at high speed. The maximum speed is 2-3m/s. 1200 series is not only widely used in box-type conveying, but also often used for belt conveyors with uncovered rollers and on friction flat belt conveyors.

Next, let's talk about the 1100 series. This series is equipped with specially developed semi-precision bearings, which have a larger clearance than precision ball bearings, and can withstand shock loads better than other series. However, the 1100 series is not recommended for the carrier roller & tensioning position of the belt conveyor. The 100 series has a maximum diameter of 50mm and a minimum diameter of 18 mm. The environmental working conditions are broad. They can be used in both high and low temperature applications, with a temperature range between -20℃ to +80℃. If you need more diameter choices, please check out the 1800 series.

The 1800 series is a rough product, that can stand hard work. The precision ball bearings are fixed in steel stamped bearing housings that are strong, durable and can withstand greater loads than the plastic bearing housings 1200 series. The full range of diameter and large bearing capacity are the advantages of our 1800 series. However, like the 1100 series, it is not recommended for carrier roller & tensioning position of belt conveyor. Temperature range between -30℃ to +80℃.

Non-powered roller conveyors are the simplest and most widely used conveying method. Of course, our non-powered roller conveyors are widely used and well known! I hope everyone can remember us.