Europe

中文

English

Europe

Welcome to Damon Industry Website

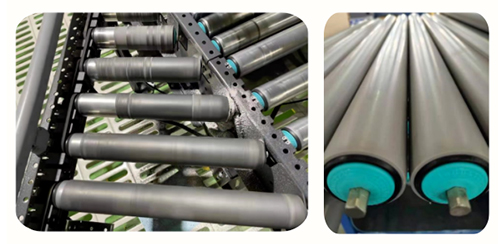

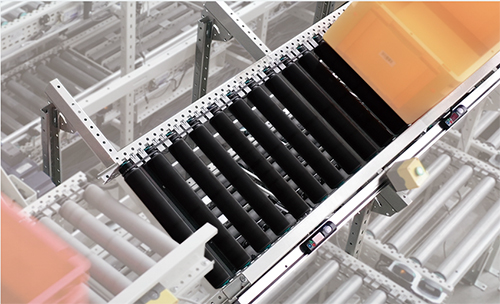

In recent years, China's on-site logistics and factory automation have developed greatly, and various systems and stand-alone solutions have emerged one after another, making our warehousing, distribution, conveying and sorting getting more and more efficient. As the core component of our conveying and sorting system, the application scenarios of rollers are increasing, and the requirements for rollers are constantly changing and enriching. The application of rubber coating or gumming of rollers is becoming more and more common. The main considerations of customers' requirements for rubber coated or gummed rollers are to increase the friction between goods and rollers to prevent slippage and improve the accuracy of goods stopping and also to prevent the contact between goods and the metal cylinders in order to protect the conveyed objects.

The common ways of rubber coating and gumming in the market are PVC rubber sleeves and polyurethane sleeves, all of which have their advantages and disadvantages.

PVC sleeve has no problem in improving the friction between goods and the conveying surface, in order to protect the conveyed objects. Compared with polyurethane, it has advantages in cost-saving and delivery. However, when some rollers are installed obliquely (side-to-side conveying, merging and diverging), the PVC rubber sleeve can easily shift; in addition, when conveying some angular conveying objects, it will easily cause the rubber sleeve to split. No matter whether the rubber sleeve is displaced or split, it cannot meet the use requirements of the project.

Encapsulation treatment (polyurethane) has no problem in terms of improving the friction force and protecting the application of conveying materials, but because of its processing technology and material problems, the cost will increase a lot compared with PVC rubber sleeve, which will also cause pressure on the overall budget and investment of customers. At the same time, the delivery time will also increase by a long period (the delivery time of the same specification is about 2 weeks longer than that of gummed rollers).

As a pioneer and leader in the domestic roller industry, Damon Industry is always close to its customers and listens to their troubles and suggestions on roller applications. As analyzed above, there is always the problem that the low-cost PVC cover cannot meet certain applications, and the coating treatment (polyurethane, rubber) that can meet the application has a high cost and long delivery time. We have been trying to find new solutions to our customers' problems, and have been working with our suppliers for more than ten months to develop a polyurethane sleeve solution. This new polyurethane rubber sleeve has been tested over a long period and has been proven to be able to prevent the rubber sleeve from moving sideways, and its material characteristics can also effectively prevent splitting. Compared with the traditional rubber coating process, its cost and delivery time have been greatly improved.

Damon Industry is changing only for you (the customer).