Europe

中文

English

Europe

Welcome to Damon Industry Website

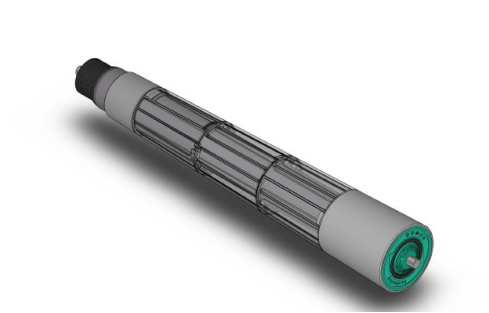

Why is tapered sleeve roller becoming more and more popular?

On the one hand, in box conveying, roller - type curve conveying solution, compared to transfer loading, has unparalleled advantages in efficiency and economy. On the other hand, the tapered sleeve roller enjoys a quiet-running, good appearance and effective protection of the bottom surface of conveyed objects.

Is the tapered sleeve roller reliable?

At present, most of the tapered sleeve rollers on the market employ an interference fit between the taper sleeve and steel pipe. This design boasts a simple structure and its convenience for production, but in some applications, it may cause some problems:

1. The fast conveying may result in centrifugal force exceeding friction force and the conveyed objects drifting outward. During this process, the conveyed objects may produce a reaction force in the inner radius direction on the surface of the taper sleeve.

2. Overload or local overload (The conveyed objects are not flat bottomed, therefore certain taper sleeves bear the full weight of the goods), may lead to the creep and loss of elasticity of the materials, and failure of the interference fit.

If the above two situations exist for a long time, the risk of loosening and slipping of the tapered element on the roller steel pipe will be increased.

How does the tapered sleeve roller made by Damon Industry prevent the taper sleeve from loosening and slipping?

As part of its product optimization strategy, Damon creates a new solution.

It adopts a new design concept and abandons the traditional interference independent fit. The creative physical connection structure allows the taper sleeve to be firmly "nailed" to the steel pipe; the integrated design makes the assembled taper sleeve connected to each other, just like warships connecting both ends to realize more stable marching and operations.

Such an innovative design avoids the risk of loosening and slipping of the tapered element to the greatest extent. More ingeniously, all optimal designs are hidden inside the roller, not at the expense of conveying stability or user experience.

What else has the product improved?

● Stronger tolerance: simulating all kinds of harsh working conditions in professional laboratory environment for targeted improvement of materials and structures;

● Wider adaptability: The conveying surface of the tapered sleeve roller has increased to 895 mm for conveying larger - sized goods.

● More versatility: The diameter of the small end has been readjusted with the taper of 3.6° unchanged.

● An optional anti-static taper sleeve is provided to adapt to the application scenarios with this requirement. (Please note that the anti-static taper sleeve is in black).

No worries around the curve? Just choose Damon Industry!

Now, the newly-designed tapered sleeve roller has been ready to serve you.

As a world-renowned supplier of transportation equipment parts, we are constantly committed to improving the competitiveness of our products through the product optimization strategy and to meeting the increasingly diversified demands of users, empowering experienced customers in the logistics to show their talents.