Europe

中文

English

Europe

Welcome to Damon Industry Website

Even if the light-duty application belt conveyor for indoors developed rapidly in the past decade, there are still no design manuals comprising standards, clear guidelines and instructions available in the industry. This is why many designers rely on their own experiences and keep a high margin of safety, as to be able to give safety to the project.

With the rapid development of the logistics equipment industry, especially of the domestic express delivery and the e-commerce industry, the demand for belt conveyors has increased significantly. To what it concerns new projects, new product applications and new design engineers, choosing the most suitable design for belt rollers is a difficult or risky work. Zhejiang Damon Industry is ready to do the following, so to be able to solve the customers’ problems:

1, Sharing experience:

Damon Industry is a public supplier of conveyors and conveying equipment. Due to working with many customers, we manufacture products so to meet different uses and requirements and we would like to share from our experience with you. For example, the coating applied on the surface of the belt rollers is usually used to increase friction, but it is relatively easy to wear. Based on our experience, we recommend polyurethane as a surface coating, so to reduce wear and to increase service life. Also, considering the high cost of polyurethane, we optimized the design structure so to remove the unnecessary polyurethane from the layer’s thickness and now the belt roller’s cost and performance are well balanced.

2, Selection support:

Damon Industry’s standardized belt conveyor pulley tension force can be charted & digitized so that designers can choose the belt model and the belt tension adjustment range easily, while also ensuring reliable operation during adjustment and debugging. In this way, there are certain things that can be avoided, like the abnormal sound caused by excessive tension, belt roller overload damage and short-term wear of the belt, thereby greatly reducing maintenance costs and the risks and costs associated with end-user equipment’s downtime.

3, Recommendations for selection:

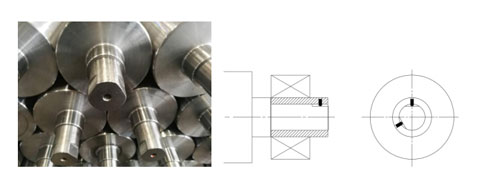

For the common short-distance belt conveyors, especially head-driven belt conveyors, the belt tension is often high, and the driven rollers at the extremities are prone to wear and failure. When applying such high belt tension, Damon Industry recommends customers to increase the shaft diameter of the driven roller to make it more resistant. At the same time, because the structure is external to the bearing, we also recommend customers to use a V-shaped flat milled shaft to avoid the relative rotation between the shaft center and the inner ring of the bearing.

From the beginning, Damon Industry has been using a standardized industrial product to provide customers with reliable and durable rollers for the belt conveyors, while also offering selection and support services to make sure that the customers will choose to implement the most suitable and cost-effective solutions. Our belt rollers - standardized industrial products, have been used by well-known customers such as: SF, Shentong, Zhongtong, Yuantong, Yunda, Jingdong, Cainiao, Vipshop and other sorting and distribution centers.We believe that a stable quality gives customers the guarantee that the product is working properly.