Europe

中文

English

Europe

Welcome to Damon Industry Website

This story begins with a package.

The yellow kraft paper is a bit dim in the light, with some oil stains on it. As the paper bag is cut apart by the sharp knife, a broken 'body' comes into sight. My mind is taken back to the crime scene.

'Crime' scene A

1. Details of the case: In X, 201X, an e-businessman reported a case of roller fracture. The 'object' involved was the pressing roller of 2240 series.

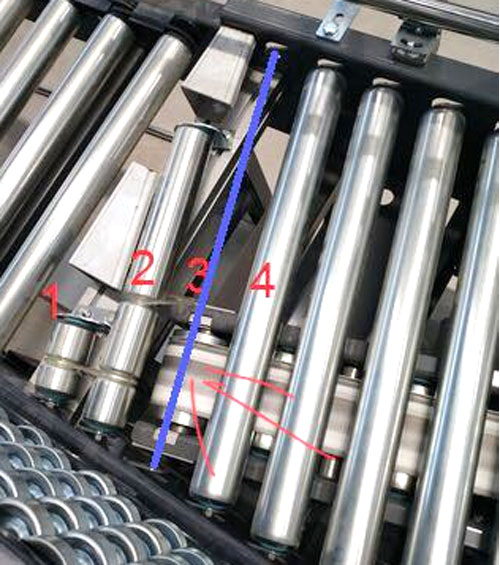

2. Scene investigation: The position of the roller was the transition section at the end of the side puller and this model was provided with low tape friction drive. The objects conveyed by it were the e-business packages.

3. Roller inspection: The fracture location was the edge of the second rolling groove, the gap was parallel and level and it was preliminary judged as mechanical tear. There was no obvious scar on other parts of the roller.

'Crime' scene B

1. Details of the case: In X, 201X, an express distribution center 'reported a case' that the roller was fractured with the components falling off. The 'object' involved was the multi-wedge belt roller of 2250 series.

2. Scene investigation: The position of the roller was the transition section at the end of the side puller and this model was provided with low tape friction drive. The objects conveyed by it were express packages.

3. Roller inspection: The broken one was the fourth multi-wedge belt roller counted backwards and the multi-wedge belt wheel had obviously fallen off. There was obvious wear trace on the surface of the roller.

Whether the careful readers have found clues: both of them were bottom-belt-driven side pullers? Both were the end transition sections? Very good, you have got the sharp eyes of a spy. Along with this clue, let us restore two scenes.

Analysis of the 'details of cases'

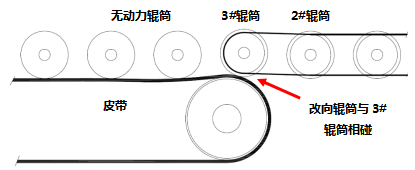

Due to the space limit, several rollers at the end of the bottom-belt-driven side puller cannot contact the belt, so the transmission rollers of other models are needed to work as the power transition.

After observation, we found the redirected rollers wearing the belts under the broken rollers (readers not understanding this structure can see the figure), and the roller surface was very near the overhead damaged roller.

It was verified through simulation that the damaged roller needed to bear the extrusion force from the redirected rollers, its surface was obviously higher than that of the adjacent rollers, showing an upwarping state. However, the structural design of the conveying roller of this model cannot bear big extrusion force, and this finallt caused the 'case' of roller fracture and components falling off.

'Case' summary

So far, the true color of the 'murderer' has been uncovered, but how to avoid it henceforward? Given the belt redirection and tension is a 'metaphysics', we only make these cases serve as a modest spur to induce someone to come forward with his valuable contributions. But undoubtedly, reasonable layout of the roller gap and the avoidance of the position of the redirected rollers need to be brought to the forefront in the design and debugging of this kind of conveying devices.

We hope this story can remind readers to avoid the minefields, to reduce the downtime or loss caused by improper application of the rollers.

See you on the next 'crime scene'!