Europe

中文

English

Europe

Welcome to Damon Industry Website

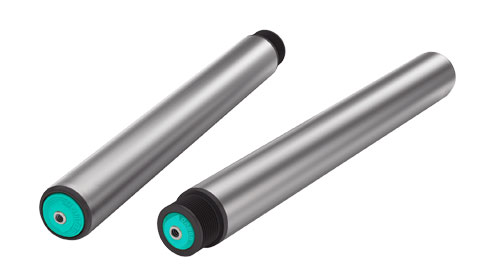

The multi-ribbed pulley plays an increasingly important role in roller box transportation in the field of logistics equipment industry. However, due to its natural “belt drive” properties and the current market situation, if made of plastic materials, it is not environmentally friendly. Many of our clients ask for Damon Industry’s multi-ribbed belt roller 2250 series to be made of metal.

Our opinion: none of the products are flawless. Both plastic and metal have advantages and disadvantages when it comes to features and capabilities. In the following paragraphs, we will analyze them separately:

Handling capacity:

Belt drive power transmission relies on friction. The main material component of the multi-ribbed belt is rubber, which has a significantly lower coefficient of friction than metal. As a result of related tests, we were surprised to find out that the maximum handling capacity of the multi-ribbed pulley made of metal, as compared to the one made of plastic, has been reduced by about 30%!

Wear resistance:

Regardless of the wear resistance, there is no doubt that metal is stronger than plastic. However, as a result of continuous research on pulley wear, we found out that in most of the cases the roller is used "unusually" (it is called "hard accumulation"), leading to a cargo block while the roller is still running on the conveyor line... Considering that such conditions are not so common, Damon Industry's multi-ribbed pulleys are created out of special plastic materials with a wear resistance that make our products excel in the industry.

In other words, under normal working conditions, you don't have to worry about Damon Industry plastic multi-ribbed pulley’s wear resistance. It works perfectly fine under short-term extreme conditions too.

Thermal resistance

When the temperature exceeds +40 ° C / is lower than -5 ° C, the plastic material’s performance reduces drastically. Therefore, in case of high temperatures or low temperatures, in places holding a constant temperature for a long period of time, such as an oven or a cold storage, plastic is not a very good idea. Under such conditions, a multi-ribbed pulley made of metal is necessary.

Specification diversity:

The multi-ribbed pulley made of plastic is currently only suitable for Φ50 mm rollers (also the most common specification). Sometimes, the Φ50 mm rollers cannot meet the requirements for some special sections/conveyors. Under such conditions, metal pulleys work better.

Purchase costs:

Of course that in terms of costs and delivery time, metal pulleys have no advantage over the plastic pulleys.

In conclusion:

Damon Industry’s 2250 Series multi-ribbed roller made of plastic is the best value for money.

Under special working conditions (such as extreme temperatures) and resistance considerations, use metal pulleys.