Europe

中文

English

Europe

Welcome to Damon Industry Website

Hello, everyone, I'm Yu Jun. Welcome to my research institute.

We have a lot of interesting information regarding roller application for dry goods. Remember to follow me!

Today, we will talk about the " all stainless-steel conveyor roller ". Why do you need it? How to choose the roller? What should we pay attention to? Let's find out.

【 Application Analysis 】

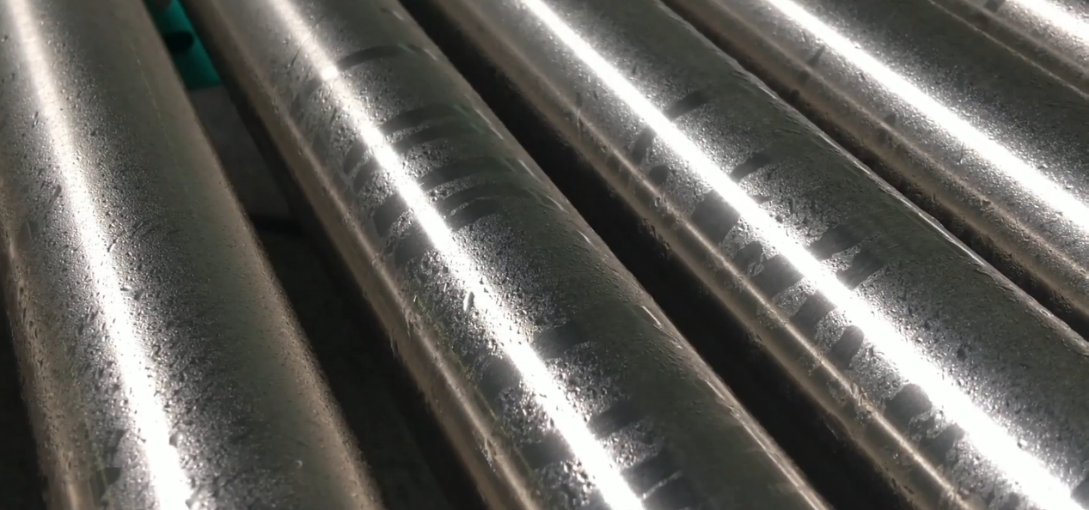

Usually, to avoid rusting too quickly, the surface of the rollers is galvanized. However, this treatment is generally only applicable to ordinary indoor working conditions and is not competent for the very humid or even drenching environment that occurs in some more special industries (such as fresh food, slaughtering, cold storage, etc.).

For the above conditions, we usually choose "stainless steel rollers". However, the term "stainless steel roller" generally refers only to the tube being made of stainless steel. The other components of the roller, such as the shafts, bearings, and even the driving elements or bearing blocks, may not be made of stainless steel to meet the high rust-proof requirements.

Such a roller, if it works in wet and waterlogged working conditions for a long time, other parts of the roller besides the barrel will still be rusty. In serious cases, it may even pollute the conveyance and site environment or affect the normal operation of the roller.

【 Results 】

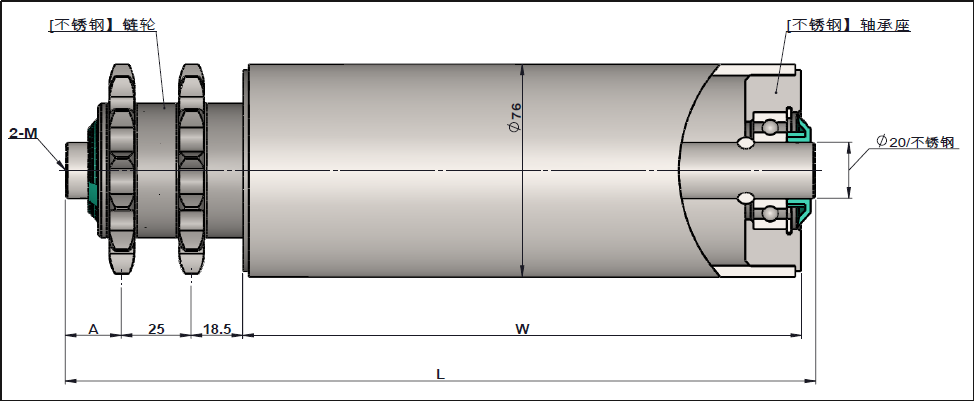

To achieve rollers that can be used properly in wet or dripping environments, it is necessary to ensure that the rollers, as a whole, meet high antirust requirements. In addition to the barrel body being made of stainless steel, it is required that all other metal parts such as shafts, bearings, bearing shells, sprockets, etc. should be made of stainless steel. This leads us to the object of our research today - "all stainless-steel conveyor roller".

Taking the sprocket roller in the picture as an example, we can realize that all metal parts including the cylinder, shaft and bearing of the roller, as well as the sprocket and bearing block, are made of stainless steel. In addition, the green plastic end caps of the head and tail have excellent rust resistance, making the whole roller flawless when facing wet working conditions.

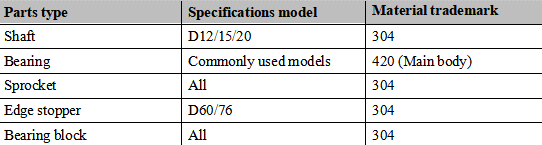

In order to facilitate your selection, the following is the list of spare parts made of stainless steel, in addition to the cylinder, which can be provided by Damon Industry:

In addition, if the stainless steel is required to be rust-proof under wet conditions (not all wet conditions), the appropriate choice is generally 1200, 2421 and other product series using plastic bearing components. Not only are they reliable and aesthetically pleasing, but they are also cost-effective.

Finally, it should be emphasized that stainless steel is not "rust-free steel", but is more resistant to rust and corrosion than ordinary carbon steel, and also has many grades of material.

OK, the above is the result of the research on "all stainless-steel conveyor roller", hope it can help you.

We will see you next time!