Europe

中文

English

Europe

Welcome to Damon Industry Website

In recent years, logistics automatic conveying plants have become more and more popular and sophisticated. Regarding factory planning, more attention is paid to the "humanized" design, the ease of operation and the comfort of the personnel being particularly important.

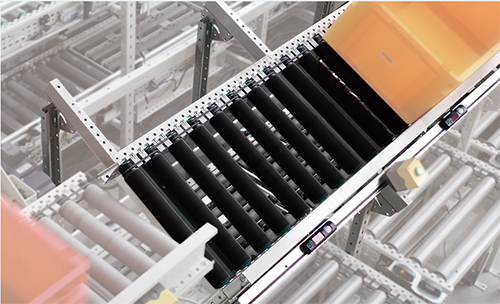

For example, in the manual sorting station of the box-type conveying line, the conveying equipment is used to convey horizontally. When picking up, personnel should often bend over to operate, increasing the fatigue degree of the staff overtime. Now, more and more stations are designed to convey obliquely, placing the box into a certain angle, reducing the fatigue of personnel when picking and placing goods for a long time.

The humanized design also brings new problems. As the conveying line is inclined, the goods will slide down during conveying, causing jams compared to the normal conveying method, or even lead to abnormal conveying. To increase the friction between the conveying object and the roller, we usually try to find a way regarding the conveying roller. Common methods of increasing friction force include PVC soft rubber, polyurethane, and rubber coating, but these three common treatment methods also have their advantages and disadvantages:

1. PVC soft rubber

Advantages: low cost, fast delivery time, and high friction surface when new.

Disadvantages: no abrasion resistance, there is a certain amount of dust, risk of lateral movement and tear of the adhesive layer, friction surface is reduced after long-term use.

2. Polyurethane coating

Advantages: abrasion resistance, tear-resistant, no dust.

Disadvantages: high cost, long delivery time, and low friction surface.

3. Rubber coating

Advantages: high friction

Disadvantages: higher cost, longer delivery time, more dust.

According to the current project requirements, it is difficult to achieve a relatively "balanced" state between the above three surface treatments. But as a leader in the industry, we are committed to providing more and more reliable conveyor roller solutions for the industry. In response to the demand for high friction for inclined conveying rollers, the PU sleeve roller has undergone dozens of improvements in more than one year, and ten months of thousands of performance tests before it was finally successfully launched.

PU sleeve not only overcomes the disadvantages of PVC sleeve, such as abrasion resistance, wear powder, risk of lateral movement and rubber layer tear, and decrease of surface friction after long-term use, but also combines the advantages of polyurethane (rubber) coating such as abrasion resistance, tear resistance, dust-free, and high friction, etc. Compared with a traditional polyurethane coating, a PU sleeve can shorten the production cycle, reduce the consumption of polyurethane materials and bring more value and competitiveness, meeting the "humanized" application.

At present, Damon Industry’s PU sleeve combined with brake roller has been used for more than one year by an international famous courier company, and has been running well, and passed the product test of foreign courier e-commerce type customers.