Europe

中文

English

Europe

Welcome to Damon Industry Website

The global epidemic that has lasted for nearly two years has had a great impact on the entire industry. However, the logistics industry has been given a whole new opportunity by the epidemic. The growing scale of the industry and the demand for transport makes it urgent to upgrade the logistics equipment technology. The annual CeMAT ASIA Logistics Exhibition will be held in Shanghai on October 26th as scheduled, and the theme of this year is "Breakthrough and Stand Up", which matches with the re-launch of the logistics industry in the post-pandemic era.

As one of the world's leading provider of roller solutions for conveying, how is Damon Industry helping the development of the logistics industry in the post-pandemic era? Welcome to visit our D1 booth in W3 Hall of Shanghai New International Expo Center.

Inherited innovative conveyor roller solutions to match customers' needs

Damon Industry has been deeply involved in the roller industry for more than 20 years. The manufacturing process of rollers has matured and the product line has been very diversified. However, based on legacy, we have never stopped innovating and exploring. We reach out to our direct customers and end-users to better understand their needs and focus on solving customer problems and enhancing customer value.

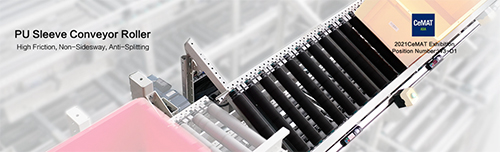

In response to the need for greater friction on inclined conveyor rollers, we have introduced a new PU sleeve roller. Compared with an ordinary PVC rubber sleeve roller, it has the advantages of more wear resistance, difficult lateral movement of a rubber sleeve and greater surface friction. Compared with the traditional polyurethane coating, not only can we shorten the delivery time, but also reduce the material consumption. It not only matches the customer's needs in terms of product performance, but also brings extra value to customers in terms of cost and delivery time.

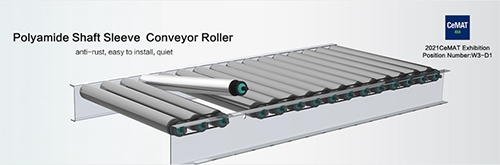

In response to the low noise requirements of high-speed conveying and the need for rust prevention in certain industries where zinc and copper are banned, Damon Industry’s plastic steel shaft roller was created. The shaft core is made of plastic steel, which can fully meet the demand for rust prevention and eliminate the high cost of rust prevention. The shuttle-shaped design perfectly eliminates the gap between the rollers and the frame, and the damping effect of the plastic steel material better meets the customer's demand for "high speed and low noise". In addition, it is selected the more efficient installation of flexible shaft mounting method, which gives customers a worry-free experience.

High load and highly intelligent electric roller solution helps customers upgrade intelligently

Damon Industry & KYOWA in high torque mode: the conveying weight is generally within 200~300kg to meet the heavy-duty conveying needs of customers. In some special applications, the electric rollers can also support ultra-high torque mode, which can theoretically provide 400~500kg conveying capacity to meet customers' special applications.

The CONVEYLINX series intelligent conveying with built-in motion cards and program customization module functions, can reduce the workload of electrical engineers, reduce on-site commissioning time and labor costs, and also enrich customers' on-site applications. Its data self-backup function allows users to achieve quick on-site maintenance and reduce the loss caused by equipment shutdown. Helps customers upgrade intelligently.

More and more product categories provide customers with one-stop solutions.

From the initial single conveyor roller product to the localized assembly and service of electric rollers in China in 2012 in cooperation with Kyowa Japan, to the marketing of high-strength welded belt rollers in 2016, to the unified management of brake rollers, a flexible gravity-based speed controller, in 2020. Localized assembly of 60 diameter electric rollers will also be realized by the end of this year, and a cam electric roller product suitable for lifting and transplanting is also planned to be launched next year. While focusing on "roller" products, we are constantly enriching our roller product range to provide customers with one-stop solutions for conveying rollers.

These new products and solutions will be exhibited at CeMAT, and there will be fun interactive games for you to experience. You are welcome to visit the W3-D1 Damon Industry booth.