Europe

中文

English

Europe

Welcome to Damon Industry Website

In 10 minutes, we created a discussion point.

During Dedao microclasses, we share everything about rollers with you.

Today's topic: Can the unpowered roller be used in the power section, what to pay attention to when using it in this way?

【Reader's confusion】

The unpowered roller is one of the most popular types of rollers utilized in a conveyor.

Most of the new users get fooled by the “un” in unpowered, thinking that conveying consists in pushing or sliding. So when having to use unpowered rollers in the power section, they ask themselves: is it be possible to use them in this way, what do we need to pay attention to in this case?

We also care for the users who reached top level roller experience and ask themselves: After using rollers for quite some time, they break, don't they?

【Time for thinking】

When thinking of “unpowered” as “powered”, first we have to answer the question of “intermediary”. Use a belt to produce friction that will make rollers spin. Based on the transmission mode, we distinguish: the transmission belt, the friction bottom belt drive, the main shaft transmission with narrow belt, etc.

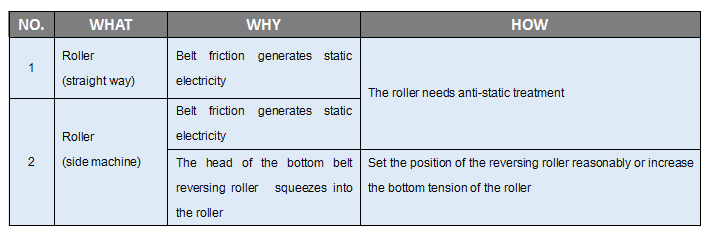

So under different conditions and modes, we have to deal with different issues. In order to answer the reader's confusion, we'll use the “WWH approach” (what, why, how).

【Dedao - Solution】

Transmission mode 1: The transmission belt

Special attention should be paid to the 1800 series of unpowered rollers, due to the use of steel components in the structure. Under the belt tension, stamped bearing shells often get damaged or even broken due to metal fatigue; also, the shock absorption effect is not as good as that of the 1200 series, so it gets very noisy when running at high speed. All in all, it is not suitable for a transmission belt.

Transmission mode 2: The friction bottom belt drive

In the friction bottom belt drive mode, roller damage is usually caused by the side alignment of the machine. Because the reversing roller of the bottom belt is relatively thick and often located directly below the transition roller, a slight mistake can get the upper roller squeezed. We have seen cases where the whole unpowered roller is lifted higher than the roller surface of the adjacent roller.

Therefore, in this transmission mode, be very careful, so to be able to avoid the problems caused by placing the reversing roller directly below the conveying roller or by adding a bottom tension roller. "Hard-to-hard" squeezing is strictly prohibited, leave the bottom belt act as a buffer against the unpowered roller.

Transmission mode 3: the main shaft transmission with narrow belt

Compared to the previous two operating modes, the main shaft transmission with narrow belt can be regarded as a derivative of the single groove roller with main shaft transmission with O-belt. There are no high requirements for speed and rollers and it is widely used in the woodworking industry.

In terms of roller selection, we also recommend the 1200 series produced by Damon Industry, because they are reliable, quiet and good looking. Regarding the anti-static treatment, based on our practical experience, the static electricity generated by narrow-belt friction is less harmful, so it's up to the customer.

【Conclusion】

Even if there is an "un" in the name, the unpowered rollers can also be "static" or "moving". But just like the old Chinese saying goes: “Gentlemen do certain things and refrain from doing other things”, our unpowered rollers roll in their own way-"nothing" does something, "nothing" does not do something. Master it, you can use rollers at their greatest potential.

That was all for today’s "Dedao Microclass". By sharing our point of view, we hope that the next time our readers will have to deal with unpowered rollers in the power section, they won’t longer be confused.

Dedao microclass, knowledge at your fingertips. Till next time!