Europe

中文

English

Europe

Welcome to Damon Industry Website

Winter has gone away and a refreshing spring breeze is blowing, blowing away the coldness in the detective’s office, but Mr. D's mood has not changed. After solving the "MDR strike" case, it seems like nothing has bothered him in a very long time.

It all started from a phone call he received that day…

“Hello, Mr. D, I have a case for you, seems like you need to come here… we couldn’t find any clues and my men haven’t had a day off in half a month.”

The case is indeed very tricky, there were no witnesses, no traces of crime, and the clues seem to have evaporated. Putting down the coffee cup, Mr.D rubbed his hurting temple and opened the notepad again.

# X day X month 201X year

# A new energy lithium battery project site

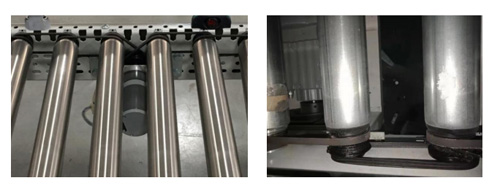

# Victim: 2250 series V-ribbed roller

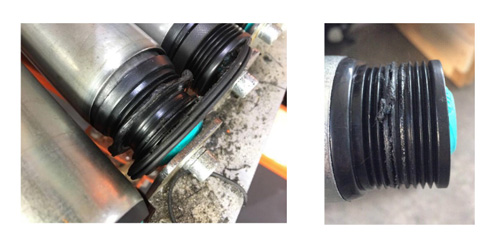

# Fatal injury: damage and deformation of the V-ribbed belt wheel’s groove

# Suspect: V-ribbed belt

# ......

The strange thing about this case is that the V-ribbed pulley is made of polyamide, a high-performance material with a wear resistance higher than of the V-ribbed belt’s BR / CR rubber. When the two are used together, it is obvious that the former is less likely to wear out and even if it happens the belt gets worn out firstly. This aspect puzzled Mr. D.

【The truth】

In order to find a direction for solving the case, Mr. D visited famous tracer, Professor W. With his help, Mr. D got an important clue, the "fatal injury" was not caused by wear. There were obvious signs of "melting".

At this point, the truth revealed.

It turned out that when the V-ribbed pulley’s roller is running normally, the "V-ribbed belt" uses friction to put the "pulley" into motion and there is no relative slip between the two. When the load increases to the point that the frictional force cannot be overcome (overloaded), the belt and the pulley undergo relative friction, commonly known as a "slip".

Friction generates heat, which either accumulates over time, or occurs frequently, eventually "melting" and destroying the pulley (rather than wear). So from this perspective, the V-ribbed belt works just like the pulley and it is also a "victim".

【Discussion】

Even if the truth surfaced out, the case was not totally clear yet. In what kind of environment did the “melting” happen? Did it happen because of excess loading? As he got deeper in the investigation, Mr. D discovered several other possibilities of “overload”, as follows:

1) The roller carried an overweight cargo;

2) Blockages and continuous running: After the goods were physically blocked, the drive was still operating (the signal didn’t break);

3) Quick start: the good tires were left on the track after the race car started, at the moment when the load was already high;

4) Emergency stop: the cargo made the roller "spin" for a while when the friction coefficient between the cargo and the roller was high;

【Post - scriptum】

What I learned from this case is that there are some sections that are prone to "melting", such are the ones connected to the power source or the ones that stop running frequently. It is also important to carefully set the maximum load capacity that applies to the transmission method of the V-ribbed belt at the beginning of the project design. Also, there should be taken into consideration the use of V-ribbed steel belt wheel + 4PJ V-ribbed belt design. But maybe the most important aspect consists in solving the "slippage" problem.

As closing the notepad and putting down the pen, Mr. D sincerely hopes that this was the last case of "melting".