Europe

中文

English

Europe

Welcome to Damon Industry Website

As we all know, belt conveyor rollers, head and tail rollers and tensioning rollers require a lot of turning operations, so everyone commonly calls them turning rollers. In order to ensure flexible processing, belt conveyor manufacturers got used to subcontracting services like design or processing, making it impossible for belt conveyor rollers to be standardized.

With the rapid development of the logistics equipment industry, especially of the local express delivery industry, the demand for belt conveyors has increased significantly, along with the demand for rollers, so the market urged the standardization of the belt conveyor rollers. However, since the market has not imposed any standards, both the belt conveyor manufacturer and the end user confronted with some problems. In order to meet the customers’ needs, Zhejiang Damon Industry has launched a standardization program in the following areas:

1. Standardization of the structural design:

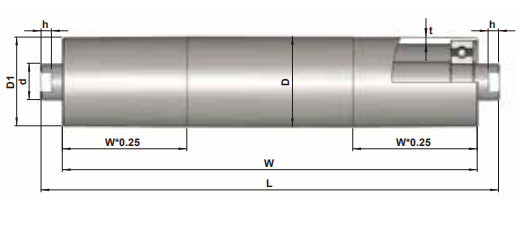

A. The roller surface is usually crown-shaped (in the image, the roller is “olive” - shaped), and the length of the tapered surface at both ends is 1/4 of the length of the roller surface, ½ of the middle is horizontal.

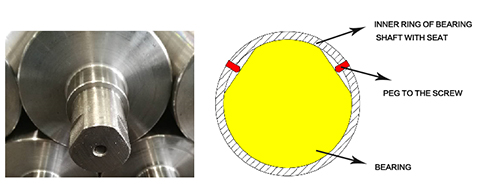

B. The BP-D series of external bearing heads are V-shaped flat. Through the relative rotation of the surface bearing ring and the shaft, we avoid the wear in the shaft, thusly ensuring a more reliable operation of the equipment and an extended belt roller life for the conveyor roller.

2. Standardization of the diameter:

Following the results of a survey focused on the customers' purchasing habits and the most popular belt conveyors on the market, Damon Industry provided the following standardized specifications:

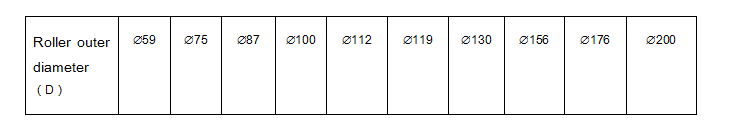

A, Outer bearing series (usually used for driving rollers and head and tail rollers)

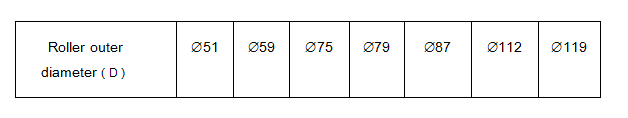

B, Outer tube series with built-in bearings (usually used for tension rollers and deflection rollers):

3. Standardization of the range of tolerance and the main characteristics:

A, As a result of understanding the product’s use and reliability verification, the shaft’s range of tolerance is standardized to meet the h7 level, so to be able to reduce excessive processing requirements while meeting the performance requirements.

B. The runout value of the roller surface is set below 0.2mm, in this way it meets requirements for most of the cases and applications.

C. In the case of rollers with a rotation speed of less than 260 rpm, Damon Industry uses high-precision pipes that weren’t applied any treatment. When the rotation speed exceeds 260 rpm - 350 rpm or when dynamic weighing is required, the product is processed to meet the level of 12.5.

From the moment Damon Industry started to provide customers with belt conveyor rollers, it used industrial product standards, instead of just providing customers with a reliable and durable product, Damon Industry tried to bring also convenience. Performance and price optimization, along with competitiveness in the customers' logistics system have always been targeted by Damon Industry. Our belt rollers - standard industrial products, have been purchased by famous customers like: SF, Shentong, Zhongtong, Yuantong, Yunda, Jingdong, Cainiao, Vipshop and other sorting and distribution centers. Stable quality guarantees customers that the equipment is working properly.