Europe

中文

English

Europe

Welcome to Damon Industry Website

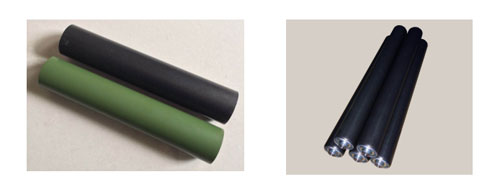

With the development of logistics equipment industry, logistics automation plays an increasingly important role in the field of processing and production. In the industries of chemical, mechanical and viscous material transportation and operation, meeting the specified hygiene requirements for food and beverage transportation is essential, and under special working conditions, traditional surface treatment methods didn’t prove efficient, so we had to find a better option. Today, we will talk about “Teflon”, closely associated to such industries. Teflon, also known as polytetrafluoroethylene in physics, is one of the most corrosion resistant materials. It is widely used for products having to meet certain acid and alkali resistance and organic solvents requirements. Teflon can be found found in the non-stick pan and rice cooker tanks.

The textile industry and the rubber industry have always been considered basic industries in China. With the development of national reforms and policies, both of them are experiencing a rapid development as well. In the textile manufacturing industry, fabrics are transported via rollers. Sometimes during transportation, there is friction between the fabrics and the roller, that can cause fabric damages, that affects production. In the rubber manufacturing industry, sometimes the rubber sticks to the roller, which leads to shutting down the equipment for cleaning. In this way, production efficiency decreases, while the energy consumption level increases.

In the two examples above, sandblasted or hard chrome plated rollers wouldn’t have been a solution. The real solution had been Teflon sprayed rollers.

Let's take a brief look at the advantages of Teflon:

1. Non-stick: none of the common substances stick to Teflon coating.

2. Heat resistance: Teflon coating film has a good thermal resistance and low temperature resistance. It can withstand up to 300 °C for a short period of time, and it can be used continuously between 240 °C and 260 °C.

3. Slidability: Teflon coating has a low coefficient of friction.

4. Moisture resistance: The Teflon coating doesn’t stain with water and oil. It hardly gets spotted with solution during production operations. Small amount of dirt are removed by simple wiping.

5. Wear resistance: Teflon has high wear resistance under heavy loads.

6. Corrosion resistance: Teflon protects any part from chemical corrosion.

It is because Teflon doesn’t wear out easily that viscous materials do not stick to its surface and the belt conveyor’s deviation is greatly reduced. In this way, the operating conditions of the belt conveyor were greatly improved. At the same time, in terms of anti-corrosion and anti-stick properties, Teflon is way better than sandblasting and hard chrome plating. Even though Teflon is sprayed on the surface of the roller, increasing its performance in many occasions, not all materials are suitable for Teflon surface treatment. For example, aluminum alloy pipe, as a light metal, has a light weight and good ductility, and has a melting point of 660 degrees. The 6063 aluminum alloy is a medium strength heat treatable strengthening alloy in the AL-Mg-Si system. Teflon's spraying process includes high temperature degreasing - surface pretreatment - spraying - high temperature curing - cooling - post treatment. During degreasing and solidification, the aluminum alloy has no strength due to the continuous high temperature state. In this state, deformation and bending occur undoubtedly and the product gets scrapped. Therefore, the surface of the aluminum tube shouldn’t be sprayed with Teflon.

It is important to choose the most suitable surface treatment for your rollers. Environments are different, as well as choices are. The annual order quantity of Damon Industry Teflon rollers is on the rise, which indicates that the roller industry interferes with many and various fields of work, which means that Damon industry is growing to be multipurpose.

Damon Industry, here to save you from troubles!