Europe

中文

English

Europe

Welcome to Damon Industry Website

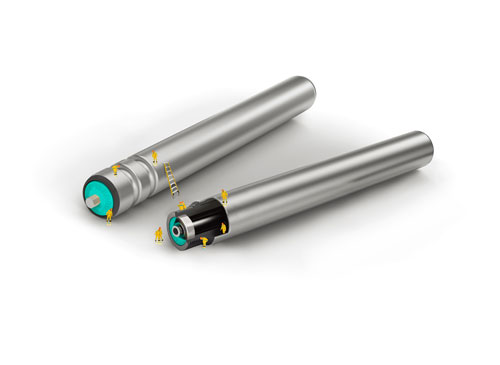

Zhejiang Damon Industrial Equipment CO. LTD promised to offer a guarantee of high quality rollers. Everybody knows that rollers are one of the key parts of a logistics conveying equipment. The quality of rollers will determine the quality of the whole transportation system. “Creating competition for customers in the logistics field” is Zhejiang Damon Industry CO. LTD’s mission. Every employee at Damon Industry Co. set a goal from delivering high-quality products.

What is a high-quality? The answer is not that simple. Damon Industry's definition is: satisfying and exceeding customers’ demands in matters of products and services.

How to reach high-quality?

1. We usually say that most valuable companies set the standards. A valuable company has a technology patent of its own and a strong capital. Also, technical parameters and product quality requirements of its products become reference for other companies. Damon Industry has been focusing on roller production nearly 20 years. As a result of a continuous pursuit of product quality, on 28th of March 2019, Zhejiang Damon Industry’s draft, “Roller conveyor standards”, was acknowledged by the Zhejiang Brand Committee. Since the 31st of March, our rollers go by the number T/ZZB 1011——2019 and have been listed as “Made in Zhejiang” products.

2. Damon Industry is strictly monitoring product quality during every stage of production. Every process, beginning from raw materials selection to quality control of products during the whole process and up to the completion of production, has to be made according to “Logistics Conveyor Roller” standards. The "Three No Principle" (rejection of nonconforming products, no manufacturing of nonconforming products, no outflow of nonconforming products) has been implemented in every stage and by every employee. Lately, our company has been busy implementing the “Red box machine” program (every employee is responsible for quality improvements), which has raised quality management system requirements to a whole new level.

3. Damon Industry supports quality management through building an intelligent factory. By improving automation, information technology and its intelligent level, Damon Industry boosted production efficiency and quality management. Smart production helps avoiding human error mistakes that could affect product quality and serves big clients with quality traceability. Damon Industry quality inspectors can carry out mapping activities by using on-site terminals. Once the inspection is over, they introduce the data into the system and the inspection report is automatically generated.

A journey of a thousand miles begins with a single step; learning has to be acquired gradually. It is all about Damon Industry people’s tireless pursuit of product quality and continuous efforts; Damon Industry has the confidence and the ability to offer a "high quality roller” guarantee to all of its customers. Damon Industry has been and will always put its customers first and by that, we understand that customers will be provided with the highest-quality products.