Europe

中文

English

Europe

Welcome to Damon Industry Website

With the rapid development of logistics equipment, more and more industries consider automatic logistics as an important way to improve the efficiency of their assembly lines or warehouses. These industries include food processing, medical care and medicine, fresh food delivery, etc. Because of the particularity of the conveyed goods and work environment, traditional rust prevention methods are not able to satisfy the needs, so better solutions shall be resorted to.

Conveyor roller is one of the most important parts in the logistics system, so how to quickly find out its prime configuration is a matter of concern for many users. Therefore, I will show you better roller configuration according to the classification of gravity roller, drive roller and electric roller in the following part.

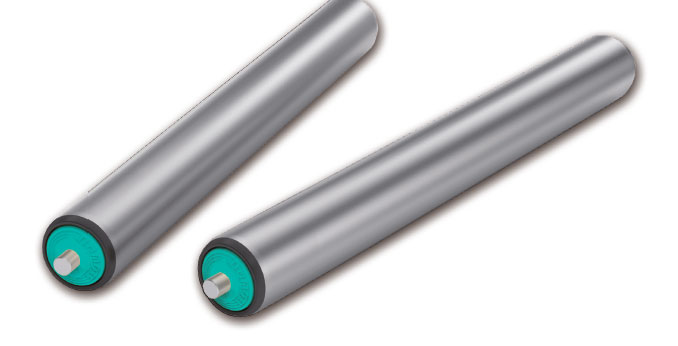

[Unpowered roller]

The 1200 series gravity roller is a classic product of Damon Industry, so rust prevention has been considered from its design stage.

Bearing carrier made of polymer material together with stainless bearing ensures the roller's excellent performance even in environment with high humidity. While the plastic end cover further reduces the influence of splashing water. Meanwhile, users can choose stainless steel, aluminum alloy or PVC according to the actual demand.

[Drive roller]

With transmission (mainly refer to O belt, poly-vee, synchronous belt, etc.)

Benefited by the serialization and standardization of conveyor roller of Damon Industry, the whole-series drive rollers developed from the 1200 series naturally "inherit" the excellent rust prevention capacity. Therefore, during the type selection only suitable tube, shaft and bearing materials need to be considered.

Sprocket convey

The 2214/2224 series polymer single/double sprocket roller use the polyamide sprocket roller as drive element to increase its rust prevention capacity. The move perfectly resolves the contradiction between steel chain wheel's poor rust prevention and stainless steel chain wheel's high price. The maximum delivery capacity of 150kg is able to satisfy the need of most application scenarios in the above industries.

[MDR]

Generally speaking, as to the ordinary humid environment (10-90% RH, non-condensing), normal MDR with stainless steel tube is able to handle; However, as to the high-humidity environment with spraying water, the waterproof MDR of Damon Industry (waterproof level IP66) shall be used.

In addition, it should be noted that the current driving card is not waterproof, so protective measures shall be taken in humid/water spraying environment.

The above is the recommended rust prevention configuration for the mostly used three kinds of rollers produced by Damon Industry. Through this kind of sharing, I hope that users can have a well-thought-out plan when choosing rollers.

Finally, I need to say the above introduction is not the only kind of optimal configuration in type selection. You are welcome to communicate with Damon Industry at any time.