Europe

中文

English

Europe

Welcome to Damon Industry Website

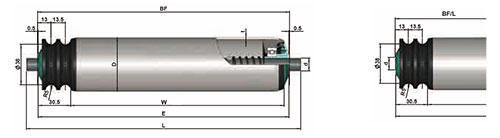

I am Damon Industry’s driven conveyor roller. I am an important member of the Damon family, you must have seen me on the belt drive and on the chain drive.

Did you notice? You must have seen a lot of products that are similar to myself in matters of length on the market, but have you ever looked at us carefully? Am I different than them?

O-ring pulleys and multi rib belts are used for the quiet and quick transportation of a light cargo. Did you see that during the process, belts get worn out to the extent that they fall off, while the rubber gets fragmented and the teeth break?

Steel sprocket rollers are used for the slow transportation of a heavy cargo. Have you ever dealt with severe worn out of the sprockets, broken sprockets or sprockets that have jumped out of the chains?

In order to avoid transportation problems, my master is like no other. He carefully chose materials and the processing methods, so I was born different. Now let me introduce myself to you!

(1) Materials:

I am made of plastic steel. Plastic steel uses a PA modified material of international brands. Its wear resistance is higher than that of ordinary nylon material. Ordinary nylon material may have air holes, may be uneven in terms of brittleness, and its size cannot be controlled when there are oscillations of temperature.

Steel sprockets and other shafts and pipes are made of a type of steel that has low impurity content and stays stable when undergoing a heat treatment process. After undergoing the heat treatment, there will be no uneven hardness. Moreover, the sprockets come with broken teeth and processed holes.

(2) Processing methods:

Plastic steel moulds are especially designed for every product structure. Precision moulds ensure the accuracy of the wedged or O-shaped products and are inspected by an image analyser which ensures the dimensional accuracy of each product.

The processing of steel sprocket is more professional. By using a high-precision shaping equipment and an advanced heat treatment equipment to process sprockets, we ensure the dimensional accuracy of sprockets, we avoid sprocket skipping, uneven tooth thickness or broken teeth.

(3) Overall :

The plastic and steel products quality is equal to the quality of processing equipment and the company’s management. Products manufactured in workshops and specially manufactured products are entirely different. Every detail was taken care of, starting from auditing, management quality and operations management, to the quality assurance of each and every roller.

My master tested and compared me with similar products on the market. Be it noise, wear resistance or stability, I am better than them in every way.

Choose us, Damon Industry will provide you with better quality products, better solutions and a better service experience. Trust us, if we’ll work together, your products will become more competitive.