Europe

中文

English

Europe

Welcome to Damon Industry Website

Encapsulation with rubber, polyurethane and PVC coatings are the three most common types of roller coatings; they all ensure friction increase, vibration and noise reduction and roller protection. Because of the similar features, they can replace one another, so that clients sometimes encounter problems when choosing the most appropriate one. As a result, Damon Industry made a brief analysis of their differences in use.

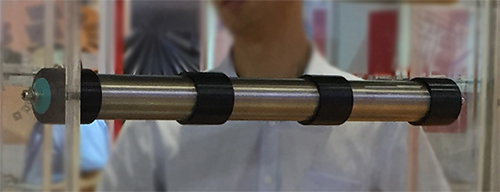

Encapsulation with rubber is one of the oldest processes of coating and it is widely used for metal and coal. It involves vulcanization, through which the rubber is glued to the roller’s surface. High friction coefficient rubber facilitates acceleration and deceleration during goods transportation.

Encapsulation is useful to the accumulation conveyor line: after the stopper is removed, the encapsulated rollers, due to the high friction rubber, can stop goods from slipping over the roller. In this way goods are quickly released and decongested.

However, friction intensifies with time and because of its natural characteristics, the fine rubber coating peels off. Commonly known as “dropped powder”, it can cover and alter the products.

The polyurethane coating. Polyurethane is poured and molded into the surface of the roller. Polyurethane’s high wear resistance makes it very durable and it is commonly used in the transport of medium-duty loads. Compared to rubber, it is more durable and also, more resistant to oils, so it can transport goods that are coated with oil.

However, it takes quite a long time to produce the polyurethane coating and for this reason it isn’t widely used.

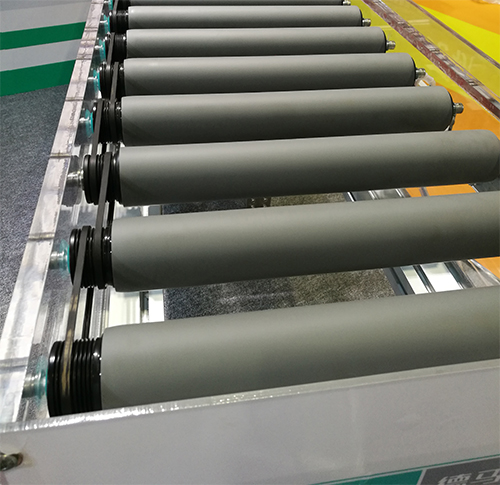

The PVC coating is totally different from the two coatings mentioned above and it is similar to a case made of rubber. The way rubber wraps around the roller depends on the tension produced by the rubber’s expansion. Even if it didn’t give outstanding results, the multi-purpose and cheap PVC coating fulfils the 3 main functions of a coating: friction increase, vibration and noise reduction and goods protection. Although it came up the latest, it became very popular, especially in the field of box conveyors.

It is mainly used for baggage security check in the airport. Due to the PVC soft rubber’s elasticity, the baggage passes security quietly, even if it is placed in plastic boxes.

However, being similar to a roller “case” makes the PVC coating not suitable for working with axial forces. Moreover, if too short, the PVC can slip off the roller.

There is no good or bad, there’s only suitable. Different needs come with different choices. Damon Industry has never stopped exploring new technologies and materials and has been striving to come up with a solution to all of the three coatings. So if you have new requirements, feel free to contact us!