Europe

中文

English

Europe

Welcome to Damon Industry Website

According to the job arrangement of Guiding Opinions of the State Council on Deepening the Integrative Development of Manufacturing Industry and Internet (GF [2016] No.28) and "Pilot Demonstration of Deepening the Integrating development of Manufacturing Industry and Internet" in Article 21 of the Working Points of the Ministry of Industry and Information Technology in 2018, Zhejiang Provincial Commission for Information Technology launched an evaluation of "Integrative Development of Manufacturing Industry and Internet Pilot demonstration enterprise".

The selection is to select a number of demonstration enterprises with the standards of the integrated management system of two modernizations, and to form a set of paths and methods for enterprise strategic transformation, management innovation and process optimization under the information environment, which is guiding enterprises to build a new capacity system under the Internet conditions, and constantly improving the level of digitalization, networking and intelligence of key industries. Therefore, it forms a number of industry application models that can be promoted and duplicated.

The main check point, which Damon Industry was ranking in the "Demonstration Enterprises with the Standards of the Integrated Management System of Two Todernizations" is as follows.

1. The new capacity building for product lifecycle innovation and service;

2. The new capacity building for supply chain management & control and service;

3. The new capacity building for modern manufacturing and operation management;

4. The new capacity building for new mode and new format.

After 10 years of promotion and optimization, the information system of Damon Industry has fully reflected that "service" and "improvement management" are two important evaluation points. These two points are embodied in the following aspects:

1. Service to customers

Technical service (product selection and detailed enquiry)

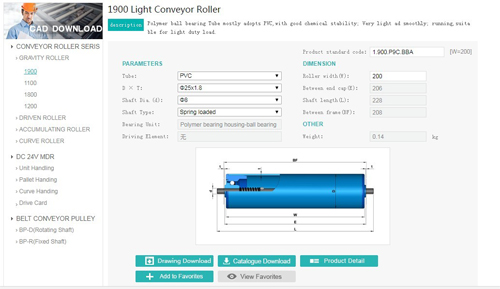

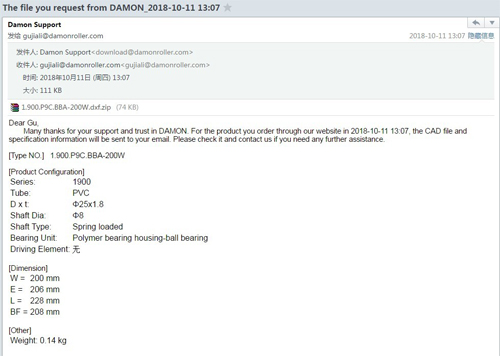

This value-added service can be used for the selection and detailed inquiry of the three products produced by the company, which are "conveyor roller", "MDR" and "belt roller". Customers only need to log in the company's official website on the computer, and click on the "product selection support". Making a choice in the corresponding property bar according to their actual needs, customers will be provided suitable roller series and models, and recommended the most appropriate roller products by the system. After confirmation, customers can download the drawings and the system will form a "product standard code", which is unique and contains all the data of the product ordered by the customer.

After 10 years of promotion and optimization, the information system of Damon Industry has fully reflected that "service" and "improvement management" are two important evaluation points. These two points are embodied in the following aspects:

2. Service to suppliers

Aligning with the company's ERP information, Damon Industry has integrated all the suppliers into the platform's management by synchronization. When confirming the purchase information, the supplier has received the purchase information synchronously, including drawing information. The supplier's delivery will be synchronized to the company's incoming inspection interface. The company's warehousing information will be notified simultaneously to notify suppliers of invoices, payment and so on a series of work done. Therefore, the platform has greatly improved working efficiency and accuracy of suppliers, and has been highly praised by procurement units, especially galvanizing outsourcing units.

3. Service to the operation of company

A: In addition to sales contracts, a closed loop ERP system has basically no manual input port, which greatly improve the accuracy of data transfer.

B: The MAS system of production enables all links of production to be synchronized and controlled, so as to ensure the commitment of customer delivery. In 2018, the customer's punctual delivery rate is 91%

C: There is no paper-based drawing circulation. All technical information and inspection information are displayed in the information. The accuracy of processing is up to 96%. Customers' complaints have been at low level with 0.67%.

The operation of the service will ultimately make customers save trouble and free from worry. There will be almost no error in the back-end as long as the front-end order information is confirmed correctly, which ensures maximum accuracy.

Since our informationization achievements fully meet the requirements of this assessment, Damon Industry finally stood out amid a large number of participants and won this honor.