Europe

中文

English

Europe

Welcome to Damon Industry Website

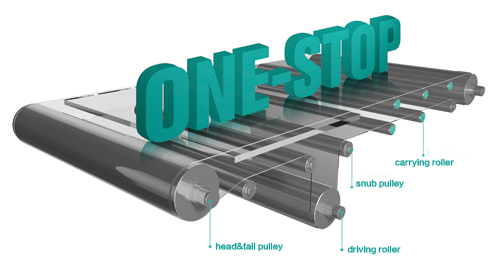

The belt conveyer is widely used in industry production as a kind of universal conveying equipment, designed to ensure a continuous flow. Compared with the roller conveyor, it has the ability to transport bulk and small articles. As one of the core components of the belt conveyer, we provide different types of rollers according to their functions. The following questions are often overlooked:

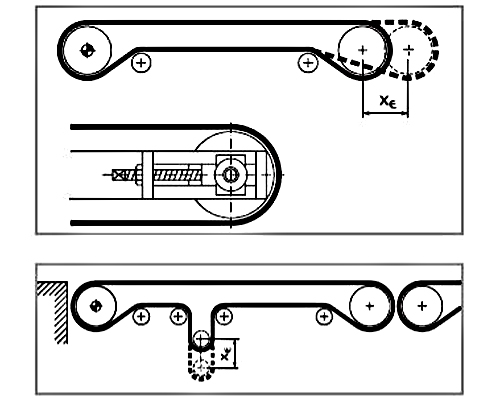

1. Can the carrier roller idler be used for tensioning?

The roller support is widely used for belt conveyors. It can effectively reduce the frictional resistance of the conveyor and it is more suitable for long distance or large load transportation. However, do not use the rollers (carrier roller) of the support belt for various forms of belt tensioning, even for small contact angle, because the resulting tension can damage the rollers.

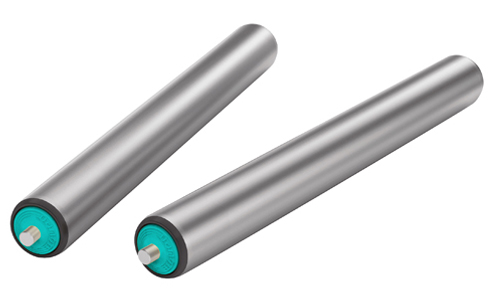

2. Is the support roller idler an ordinary unpowered roller passive roller?

The unpowered roller is a passive roller. The roller rotates only when the goods pass by, being a low intensity roller. In the case of support rollers, the belts are the goods and between the rollers is an uninterrupted movement. The electrostatic problems are often ignored and proper measures must be taken in the design of the support roller in order to remove the large amount of static electricity caused by the high-speed friction between the roller and the belt (also applicable to bottom belt friction conveyors).

3. How to reduce the rolling noise?

The noise comes from the vibration of the rollers during high speed rolling, so it is necessary to ensure that the connection between the roller and the frame is not "loose". In this case the performance of the thread is obviously better than the spring. Of course, other measures can be taken to eliminate the gap between the central spindle and the frame mounting hole. In addition, we recommend the use of Damon Industry 1200 Series. The design of the silent bearing assembly, in terms of sound absorption and noise reduction, has an excellent performance compared to other products.

4. How to make the driving roller "achieve twice the result with half the effort"?

Choose large diameter driving rollers and you will notice that the belt conveyors are more powerful. In addition, you can cover the outer surface of the driving roller with polyurethane (or encapsulate) to increase the friction, thereby improving the driving ability. However, we do not recommended knurling, which is also a way of increasing friction, because it can damage the belt and shorten the belt’s service life.

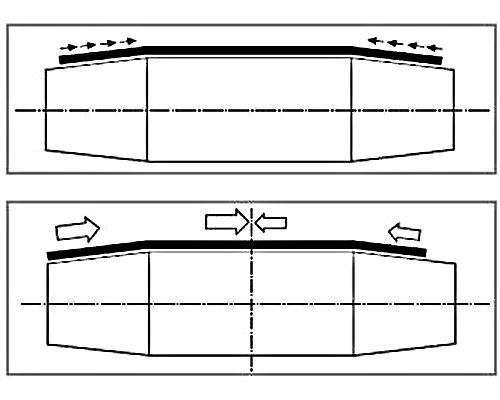

5. Is there an inexpensive correction design?

Rectifying deviation (also called "adjusting deviation") is a problem that all belt conveyors have to face, especially for bidirectional conveyors. The system engineering needs to have a special rectification mechanism design. When there is no special application such as lateral feed with large axial external force, we recommend the drum type design, the conical ends rollers, having a self-correction function. (For details, please see "Introduction to Damon Industry Belt Roller Products")

6. Adjustment of high-speed belt roller mobile and static balance.

Due to the uneven internal structure of the raw materials and the shape errors caused during machining, in practice, even when the roller is revolving, the turning device center and the center of rotation do not completely coincide, being in a non-equilibrium state. At high speed, it will cause strong vibration of the roller and even the frame, accelerating the wear of the bearing, shortening the mechanical life length and causing serious destructive accidents. According to different applications, Damon Industry can provide adjustable, mobile, static balance belt rollers.

7. Diameter selection for the head and rear rollers.

When the belt conveyer adopts intermediate drive instead of end drive, we don’t recommend large diameter for head and rear rollers, driving capacity is far less obvious than that of large diameter driving rollers, increasing the gap between the front and rear conveyor, being easy to get stuck.

The above pictures represents the design and type selection of some belt conveyor rollers. Hope it’s helpful! If you have further requirements, please contact the professional belt conveyor roller provider: Zhejiang Damon Industrial Equipment Co., Ltd. for consultation and understanding.