Europe

中文

English

Europe

Welcome to Damon Industry Website

Aircraft engine is the "shaft" of all aircrafts, and the chest reactor is the "shaft" of the Iron Man, therefore bearing is undoubtedly the "shaft" of the roller. It is the most important and irreplaceable part. Its quality directly decides the roller's performance, which is like a flash in the pan or the relentless movement of water.

The bearing is a standard part with various types. There are "limitations" in the bearing since it is used in so many industries and different fields, and oriented to different using requirements, therefore it needs to be segmented and applied, and also shall be treated differently.

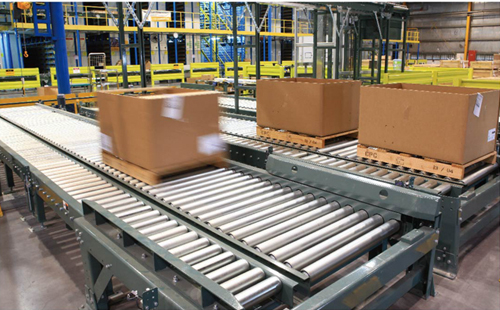

For the conveyor roller in the logistics equipment industry, compared to motor production and other similar industries, it has low revolving speed, larger carrying capacity, certain impact load and resistance to large flexural deflection and other characteristics. To promote the products to have better performance, Damon Industry cooperated with many professional bearing manufacturers in developing the bearings (we call them as DCB, Damon Customized Bearing) which are suitable for conveyor roller many years ago, and has used them to this day.

With the rapid development of the logistics equipment industry and the rapid advancement of technology in recent years, the previous generation of DCB urgently needs to be upgraded and transformed. Through more than a year of development and testing, Damon Industry has fully implemented the new "shaft" since 2018 and used Damon as its new mark. Compared with the previous generation, it has made following improvements:

1. Completely cancel the non-standard design of lengthened inner ring and optimize the configurations for different rollers and bearing types, which will greatly improve the level of universalization.

2. According to different application needs, the raw material of the bearing is adjusted to improve its structural strength and load capacity.

3. On the one hand, the carefully selected grease type and appropriate grease injection proportion promote the applicable temperature range of the bearing to be further expanded. On the other hand, the natural conflict between the lubrication ability and revolving resistance is well balanced.

4. The radial internal clearance is refined on the basis of group C3 so as to make it have a stable working internal clearance and the rollers run more smoothly and quietly.

With the continuous improvement of its own requirements and the pursuit of quality, Damon Industry rollers have withstood many harsh tests of the international industry giants, and increasingly obtained approval and have served factories and warehouses, airport logistics, distribution centers, etc. around the world. Even for some services, after nearly 10 years, the rollers are still reliable and usable. In the pursuit of excellence and consistency enterprise spirit, Damon Industry has never ignored any details, and has forged ahead with the focus on "shaft" with more professional products and services.