Europe

中文

English

Europe

Welcome to Damon Industry Website

The various opportunities brought about by the rapid development of the logistics industry are self-evident. The conveyor equipment in logistics and warehousing can be said to be its “big heart”. It is constantly pouring new blood into the industry which is vibrant like a teenager. If the conveyor equipment is said to be the “big heart” of the industry, then small rollers can also be referred to as “lubricants” for the conveyor equipment.

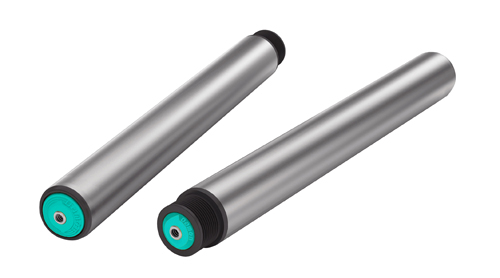

Multi-ribbed pulley roller, as a commonly used product on conveyor equipment, has its own features: Multi-ribbed pulleys are made of polyamide material (plastic steel). Compared with traditional steel materials, they are of the advantage of low running noise, and there are 9 grooves on the pulley, and the matched multi-ribbed belts are equipped with 2 grooves, 3 grooves or 4 grooves. The customer can select the corresponding multi-ribbed belt model flexibly according to the weight of single-zone conveying goods, and no matter which type of multi-ribbed belt adopted, there are grooves between the two belts when installing, which can avoid the loss caused by the friction between the two belts.

Although the above advantages are so “exciting”, Damon Industry’s concept of continuously improving the products will not change. According to customers’ feedback, abnormal phenomena exist on the multi-ribbed pulley rollers (inventory parts), i.e. due to thermal expansion and contraction, there will be changes in the dimensional tolerance of components in summer and winter, which will affect the assembly accuracy; and long-term operation of the rollers has higher wear-resistance requirements for the performance of our multi-ribbed pulleys, otherwise groove wear and even hot-melting are likely to occur on the multi-ribbed pulleys. To this end, the Damon Industry team and the supplier carefully studied the relevant materials on the market, customized materials, and after several times of wear-resistance test for multi-ribbed pulleys, they eventually found the “Mr Right” in mind. The new material has a good performance in terms of wear-resistance, which has effectively solved the abnormal problems in the inventory parts, enhanced the performance of the products, solved the customer's concerns and provided a guarantee for the reliability of the equipment.

“Standardizing Management, Continuously Improving, Customer First, Quality First”, the 16-character principle is so eye-catching, then, “stubborn” Damon Industry will be all the way “stubborn” to create greater value for customers and continue to move forward.