Europe

中文

English

Europe

Welcome to Damon Industry Website

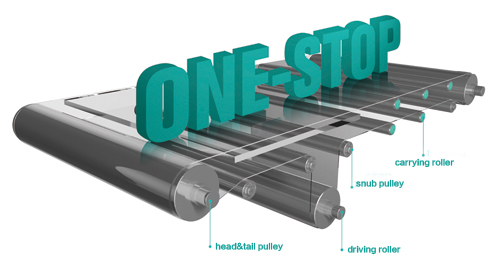

When it comes to the security check equipment, people tend to think of the personal security check and product security check in airports, customs, frontier inspection and wharf. However, with the high-speed development of the modern logistics industry, the operation and management of the logistics industry has also been increasingly heavy. In particular, the safety control of the express parcel directly influences the safety guarantee of people's life. Therefore, the security check equipment faces the requirements of high-tech, high efficiency and high information. Although the transmitting roller on the security check machine is not the high-tech product, yet it directly influences the operation efficiency of the devices. The performance quality of the roller directly influences the stability and reliability of product transmission. In case of the large travel flow the Spring Festival travel and the National Day, continuous stability of security check equipment seems extremely important.

The XX company located in Shenzhen, Guangdong gives the feedback that as the leading enterprise in the security check industry, it has a large use amount of roller per year; however, it still uses the old-style welding vehicle-made roller in the transmitting roller installed on the security check machine, which has the problems of jam, abnormal-sound rotation and short service life after it is jointly used with the belt. These problems tend to lead to the phenomena such as the equipment off-stream, noise pollution and continuous increase of the maintenance cost. The quality issue of the roller has been hindering the corporate development. A roller with stable performance and excellent quality is urgent.

Therefore, we recommend the belt roller exclusive for the belt conveyor to the client and make according technical improvement by combining the actual demands of clients.

1. Through the constant attempt, technical adjustment, frock improvement and reduction of the roller chattering, chattering is guaranteed to be within 0.2mm, which can not only guarantee the stable product transmission, but also reduce the imaging joggling of the security check equipment and improve the security check efficiency.

2. Through control of the tolerance preciseness of the belt axis excircle, its gap with the axis meets the client's requirements. The combined use with the 1200-type roller of our company can effectively reduce the roller noise and improve the working environment.

3. Through adjustment of the belt roller technique and structural optimization, the degree of adaptability between the axis and the bearing is strengthened and the axis wearing degree is also reduced, so as to make the roller more durable and reduce the maintenance cost of the equipment.

Through the above improvements, the use problems of the roller have been solved one by one. It has increased the product competitiveness of the client; meanwhile, the brand uniqueness brought by the high quality also makes the client enjoy a higher reputation in the industry. In addition, Damon Industry has sent the samples of different specifications to this unit, so as to satisfy the client's test of the equipment with different models; the client is very satisfied with our service quality and is moved by our tireless and sincere attitude. The result of sample test also satisfies their technical demands. Client shows that it will continue to adopt our Damon belt roller in the subsequent equipment. Meanwhile, they also hope us to give more technical supports and provide more references for the design of their subsequent projects.

About 20 years, Damon Industry has been focusing on research and development of conveyor roller and manufacturing, inheriting the craftsmanship and pursuing perfection!