Europe

中文

English

Europe

Welcome to Damon Industry Website

After twenty years of development, especially in recent years, with the blowout increase, the volume of China's e-commerce transactions exceeded RMB 5 trillion in 2016. In order to improve the efficiency of sorting and distribution, more and more equipment and systems with high technology content will be adopted. As the key equipment in the automatic sorting system, the sort machine has been widely applied with its high sorting efficiency up to 6,000-12,000 cases / hour.

[Challenges]

Automatic sorting equipment (such as cross belt sort machine) is usually equipped with dozens or even hundreds of sorting passes (lower passage pass). Small quantities and multiple categories have become normal, which requires that every slideway of lower passage pass can be used to slide the goods of different weight (vacuum package of rice, the whole case of mineral water, chocolate cookies, baby diapers, etc.). In case of the standard roller, if the design angle of slideway is too large (steep), the heavy cargo will slide too fast. Then it is easy to damage goods, and there are also security risks; however, if the design angle of slideway is too small (slow), the light cargo will not slide. Although the initial speed of sort machine is used to "rush" them, once accumulations occur (frequently), the initial velocity is zero when it is released, and it cannot be slipped with an awkward circumstance.

[How can we do]

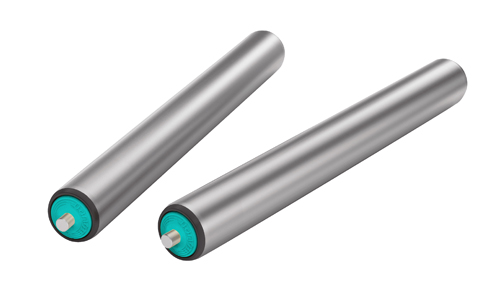

Change the traditional roller design idea, and Light Running roller is customized suitable for the use of the slideway according to the specific use conditions and application requirements:

1. Screen suitable raw materials and optimize pipe making process, to greatly improve the static balance ability of tube stock;

2. Make design and adjustment of bearings in many aspects, such as oil, groove curvature, clearance, seal and so on, to reduce the rotation resistance, withstand the impact of the application, and have good adaptive ability;

3. Further control the warpage deformation of plastic parts through mold flow analysis, and multi point gluing process for hot runner is adopted to ensure that the key components are in line with the design requirements;

4. Equipment technical modification and special molds complement each other, which can improve assembly precision and ensure the product consistency at the same time;

It is through this series of adjustments that the rotation resistance of the roller has been reduced by about 50% compared with the standard roller. Taking the generic specification as an example (diameter: Φ50 mm, length: about 600 mm), Light Running roller has the ability to fall down with the 200g parcel at the 9°slideway.

It is undoubtedly that slideway of Light Running roller is the most economical choice without cost increase through comparison with other solutions and years of practice. The gravity of traditional and green way can solve the problem that how light goods can slide in the small angle slideway, and the design is simple and flexible. It has won the wide trust of customers through reliable and stable product performance. Now more than 3 million branches Light Running rollers of Damon Industry have served the high-speed sorting system of logistics distribution centers around the world such as Amazon and DHL.