Europe

中文

English

Europe

Welcome to Damon Industry Website

With the advancement of Industry 4.0, industry enterprises have higher and higher requirements on the functions, quality, precision and efficiency of their products. In the operation of conveying equipment, it is often found that roller bearings produce abnormal sound, jamming, high temperature, or even bearing damage. If a roller in an operating device fails, the entire equipment or assembly line has to stop running, seriously affecting the production efficiency.

According to the customer feedback, Damon Industry made related failure analysis, they are: coaxiality at both ends of roller inner bore, roundness of bearing hole, the size (meter) of the inner hole and the like In order to avoid and reduce the occurrence of such incidents, we tested relevant samples and found that improving the accuracy of products to reduce errors can avoid and reduce the occurrence of similar events such as bearing noise, jamming and so on.

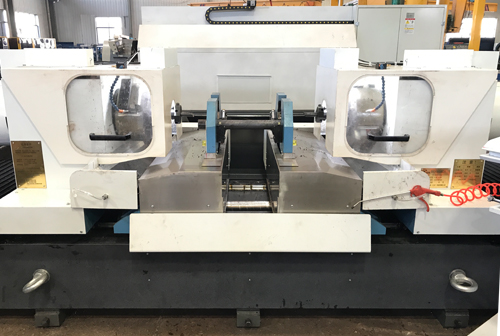

In March 2017, the company introduced the most advanced fully automatic double-head boring machine. After six months of use and analysis, the double-end hole drilling machine has greatly enhanced the precision, quality and production efficiency of the machine-cutting roller products.

Ⅰ. The improvement of product coaxiality

The quality of the roller and shaft is the key to the service life of the roller. It is the difficulty that ordinary processing technology cannot guarantee and also the product quality data that customers are most concerned about. The smaller the coaxiality error of the two ends of the roller, the less the friction generated during the operation of the bearing, the smaller the amount of heat dissipated by the friction and the longer the service life of the bearing. The use of full automatic double-head boring machine solves the difficulty that the error of coaxiality is big in the product processing. Through product inspection, in e terms of the products made by double-head boring machine, coaxiality of work-piece is guaranteed ≤ 0.02mm - 0.03mm, the workpiece size of seam allowance roundness is ≤ 0.02mm, fully meeting the requirement of the product technology.

II.The improvement of product accuracy, and processing efficiency

In order to ensure the quality of products, ordinary processing is more complex. After the pipe starts to be made, the rough machining on the surface is conducted first, and then the rough machining on the inner hole, where the center frame and U-turn processing must be used. After this processing, the finish cut of the inner hole is conducted, the purpose of which is for the coaxiality and the roundness of inner hole of the product. In the ordinary processing, complex processes, high production costs, and unmanageable product quality resulted in the poor market competitiveness.

Full automatic double-head boring machine employs middle bi-directional V type clamping mode, the processing range of 500 mm – 1,400mm, meeting the needs of various models. The process is simple. After cutting, the pipe is loaded directly, clamped once and processed in the way of two-way simultaneous processing, molding at a time. Based on the processing parameters record statistics of thousands of pieces of products, accuracy of the product is stable and the inner hole accuracy is controlled within 0-0.03mm, meeting the requirements of product quality, efficiency increased by 30% or more, greatly reducing production costs and improving market competitiveness .

Through the improvement of equipment and technology, the shortcomings of the products are solved, shortening the delivery cycle of the product, reducing production costs, and removing the customer's worries.