Europe

中文

English

Europe

Welcome to Damon Industry Website

As the model enterprise manufacturing conveying roller, Damon Industry has always been based on the effectiveness, stability and consistency of product quality. Surveillance and measurement play an important role as a strong backup for quality assurance. What is the secret behind it? Let me show you around it:

Salt spray test machine: the equipment that is considered to be equipped with in a surface-treated factory has been in the measuring room of Damon Industry for the benefit of the customers in choosing the most suitable rust-proof solution. Zinc plating, black coating, chroming, antirust agent coating, hard antirust oil spraying, paint spraying and other rust prevention program will be first tested in the test center. Through the salt spray test of 72 hours, they will expose the prototype. The same process of different suppliers and different stages are constantly verified and improved to ensure that customers get a stable surface quality. Through years of hard work, complaints about the surface of Damon Industry have declined year by year. Being beautiful and having good consistency have become a common reviews of Damon Industry roller. This test machine plays a great role.

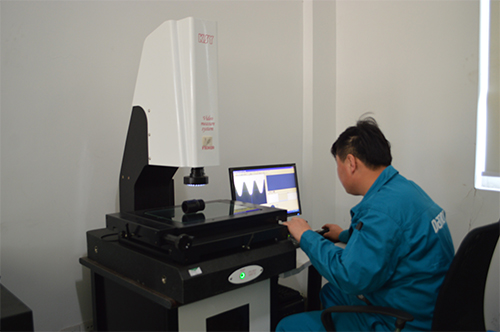

Image measuring instrument (2.5 Yuan/time): a great number of steel components and plastic components are used in pressure roller, and their roundness, concentricity, tolerance of fit and other precision directly impact the performance of finished roller products such as: Swing, concentricity, beating, loosening and other performance. In the high-speed line body, this performance must be fully guaranteed, and image measuring instrument can more accurately measure the accuracy of the parts as required. Its display resolution can reach: 0.001mm. This equipment plays an irreplaceable role in the opening mould of new products, follow-up product monitoring, sampling of stable products and so on.

Static and dynamic balance tester: belt roller, as new series of products of Damon industry, is fixed a position to enhance the running performance of medium and high speed belt conveyor, so after solving welding, concentricity, machining accuracy and other issues, dynamic balance measurement and correction are still issues for Damon industry roller to solve. Because the poor dynamic balance in the rotation process will produce a different bearing pressure, resulting in jitter, affecting the operating life and producing a lot of noise. The balance of 6.3 level is basically an acceptable value, equivalent to a roller with the diameter of 100MM, linear speed of 160 m / min, no more than 30 grams of dynamic equilibrium value. Static and dynamic balance test machine has functions such as measurement, counterweight guidance and other functions. There are already a number of high-speed projects using the belt roller of Damon Industry .

Damon Industry has focused on quality management for many years, transferring from the finished product testing to the front end and the process end, and escorting their products through professional testing. Damon Industry rollers have been doing a good job of security for the conveying equipment to be developed towards the great trend of precise delivery, high-speed delivery, smooth delivery and green delivery. Honesty and dedication is what Damon Industry always sticks to .