Europe

中文

English

Europe

Welcome to Damon Industry Website

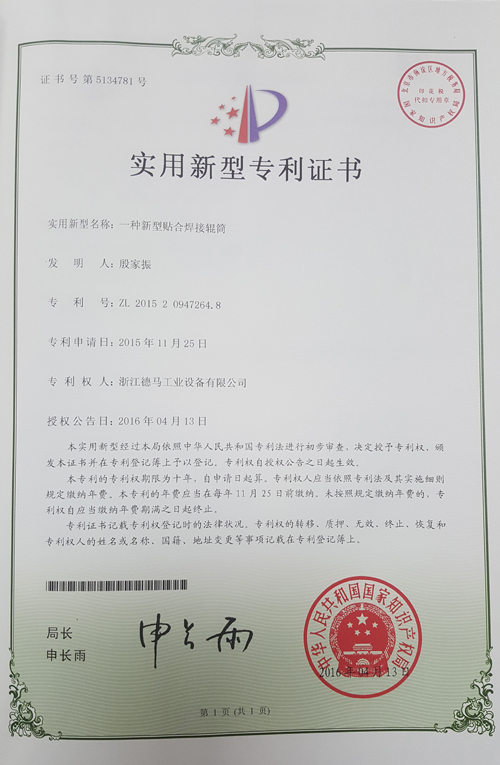

In 2016, Damon Industry won a patent “New-type Joint Friction Welding Roller” (Patent No “ZL201520947264.8") granted by the National Bureau of Intellectual Property of the P.R.C.. The patent shall take effect as of the date of the announcement.

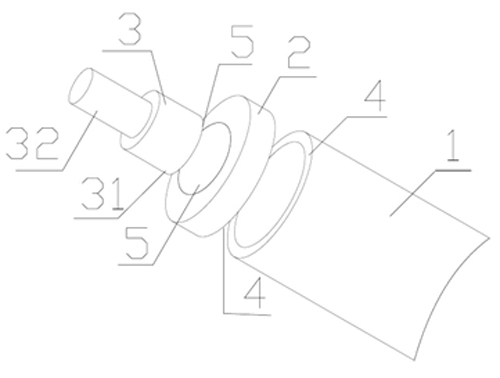

The utility model relates to a new-type joint friction welding roller. It is mainly implemented through the following plans: a new-type joint friction welding roller comprises tube and shaft, including the cover, one side of which is friction welded to the tube, another to the shaft. The side end of the tube forms a ring which is friction welded to the cover to form fusion Part I. The plate shape cover is perpendicular to both the tube axis and the shaft axis. The cover is friction welded to the shaft to form fusion Part II. The axis section radius is smaller than that of the cover.

The utility model is to provide a new-type friction welding roller, simple structure, large welding connection area, good joint, high connection strength.

In the traditional welding process, the spindle nose and shrouding is connected by the welding rod, which covers the surface of the excircle. It mainly uses the ordinary gas protection in welding. Also a third type of material has been added during the process of welding. It has not only increased the risk of mixing the impurities but the product stability is rather poor as well. While in the new welding technology, the spindle nose and shrouding is connected by the melting materials after high-speed revolution and extrusion. It has good penetration. As it adopts the automatic friction welder, the products have high stability and efficiency. For example, diameter of axleφ45mm, weld bead height 6mm, compared with the traditional welding, friction welding’s ultimate bearing capacity has been improved almost 65%. The welding strength is sufficient to withstand the strength and fatigue tests in harsh conditions.

Currently, the new welding technology is widely used in the belt roller of the newly released belt conveyor pulley. The load capacity of the high strength welding belt roller is greater and more reliable and durable. The belt roller provided by Damon Industry can operate continuously under varying heavy load and high speed conditions.

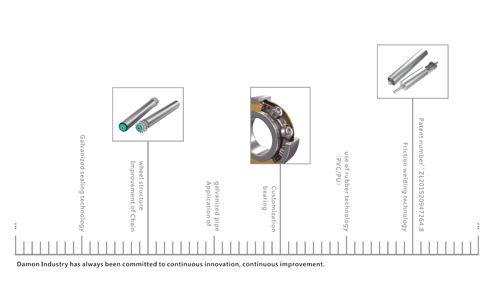

As China’s economy has entered into the “new normal” stage driven by innovation, technology R & D and innovation has become the core competitiveness of enterprise development and an important support for Damon Industry sustainable growth strategy.

Since the establishment, Damon Industry has attached great importance to R & D team and platform. Each year, 3% of Damon Industry’s sales volume will be invested in technology and innovation. In 2016, Damon Industry won utility model patents “A Kind of Roller Set Machine” “A Kind of Roller End Envelope Machine” etc.

Although the technology of rollers has tended to be mature, we are still working to seek the possibility of improving user’s work efficiency.’ From material to technology, from structure to application, from work flow to technical support, Damon Industry is taking all the innovation actions to improve the product added value.

Improving the competitiveness of logistics system for the customer through technology research and innovation is the persistent pursuit of Damon Industry.