Europe

中文

English

Europe

Welcome to Damon Industry Website

As Chinese leading conveyor roller brand, Damon Industry persevered and kept improving in the past 16 years. We provide reliable and durable logistics equipment core components conveyor rollers for various industries. In the year 2013, Damon Industry kept doing efforts in various aspects:

Hardware upgrade: moved into the new factory, improved the equipments and environment.

In March 2013, Damon Industry entirely moved into the new factory with an area of 14000 square meters and well organized layout. The company also introduced a series of advanced automation equipments with more professional production, more advanced capacity and more stable quality.

Customers have much more confidence with our products and service as well.

Service improvement.

Sales dept. has manning two external sales who monthly visiting customers to provide face to face service. So that we can deeply understand customers’ real demand to provide faster feedback and better service.

Technical dept. has manning two pre-sales engineers who can discuss application of solutions with customers, to provide professional advices to figure out the most suitable solution for customers with the most thoughtful technical support.

Marketing dept. launched new official website, with brand new aspects to serve our customers.

We added new servers for the new website to shorten the response time , provided fast download service for drawings and documents.

New products , New process , Green manufacturing

We cooperated with Japan Kyowa Mfg. on the DC 24V motor drive roller has been launched and promoted in 2013. After whole year sales, the market reaction is far beyond our expectation.

To meet the domestic customers’ demand for rich in application and mature technology, we provide value added service of repair and modification. There is not even one customer complaint for the quality and service during the whole year 2013.

We also optimized flexible rotation roller structure, fully match the customer’s requirements, with the customer recognition, we got 700,000pcs rollers oversea order for DHL sorting center.

By the new process orientation of light structure roller and less process, we launched no shaft roller, pre-galvanized tube, plastic components instead of steel components; in order to reduce cost and raise efficiency for customers by energy saving and environmental protection.

Focus on customers’ satisfaction, employee’s satisfaction and management participation

By the employee’s satisfaction survey in 2013, we found what need to be improved internally in the future, such as high frequency overtime work, noise inside the workhouse, shuttle bus etc.

While most employees are satisfied with company culture, colleague relationship, personal development and willingness of long term work.

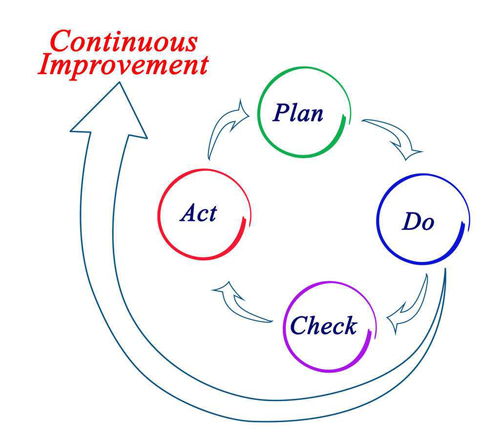

Customers and employee’s satisfaction improvement is always the motivation of company management and deserve us continuous hard working.

This time we improved the customer satisfaction survey, from procurement, technology, management three channels to understand customers demand. From the survey we found that customers are satisfied with our service quality, product stability, company creditability, technical support ; while the product delivery time and on time delivery rate is still need to be improved.

In the year 2013, Damon Industry kept more than 20% growth, and moving steadily in accordance with our expectations. In the coming year 2014, we have determined the main plans and budgets, we will keep improving our customers’ satisfaction and improving ourselves. All of Damon Industry staff will together hard working to create more value for customers