Europe

中文

English

Europe

Welcome to Damon Industry Website

With the rapid development of telecommunication technology and modern logistics technology, our world is becoming smaller and smaller.Now we could get all the necessities of life without leaving home. But behind all this, it is tens of thousands of rollers which support that. From the production line, composing room to the final products check-in and check-out the warehouse, from the E-business to the express, from China to the world, we could see rollers all the time. If compared the modern logistics system to biological tissue, the smallrollers, which seems inconspicuous, could be regarded as the ‘gene’ of logistics conveying equipment. Its quality directly determines whether the whole logistics system could run efficiently and steadily.

During the exhibition of CeMAT ASIA, fortunately the reporter has met and talked deeply with two engineer’s representatives--product manager Mr. Shengjie Li and Mr. Weibin Cao from Zhejiang Damon Industry Equipment Co., Ltd, who have given life to these smallrollers.

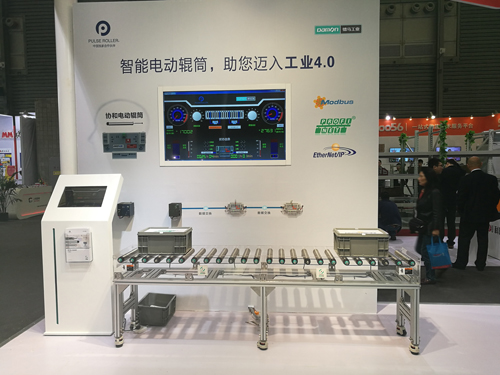

During the exhibition, the original electric rollers have been technically improved by Damon Industry. For example, the electrical machine’s pole-pairs have been increased, which makes the rollers’ location and speed be controlled more accurate. According to Mr. Shengjie Li’s introduction, Pulseroller are always being used in the roller conveying line. They support ZPA, which could make the transport start and stop frequently as required. Such distributed control makes a significant effect to the energy-saving and cost-reducing.

Now users are paying more attention to the energy saving, efficiency and intelligentize. Compared with the normal motors, MDR have more advantages in energy saving. ‘In a conveying line transformation project which was held in South Africa, our partner KYOWA has used the Pulseroller directly instead of using the common ac motor driving rollers and adopts the zero pressure product function, which saves nearly 80% electricity for the pipeline. Moreover, because the electric rollers are easy to install, as well as their space saving and flexibility, they are quite suitable for the modern transportation equipments and their growing trend.’ Mr. Shengjie Li points out.

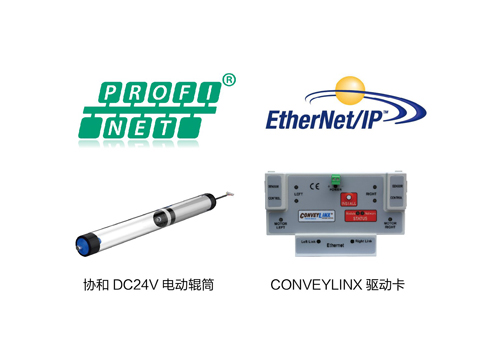

Efficiency and intelligentize has become the hottest areas of the roller products’ technological development in the future. For this, Damon Industry has the corresponding products. Damon Industry’s SENERGY, not only has improved the torque, but also adds the running modes to ECO, BOOST and BOOST-8. Customers could choose them to improve the transmission capacity and efficiency according to the actual usage. With regard to the intelligent applications, Damon Industry has pushed out driven card named Conveylinx, which could integrate the customers’ common used functions and then choose to use according to their demands. For example, pre-decelerating function, function for distinguishing the blocking and data tracking. Apart from that, customers also could write programs by themselves to make the driven card customized. The product supports many mainstream communication protocols such as PORFINET, EtherNetCat, Modbus TCP and EtherNet IP. ‘For the logistics conveyor line, customers could obtain the delivery goods’ information and condition. They could get the device state and process the roller signals. So it becomes much more convenient and intelligent in the data interaction, the conveying efficiency has been improved in this way.’Mr. Shengjie Li said. Damon Industry’s Pulseroller have become the intelligent driver element, they help customers head into the 4.0 industrial stage.

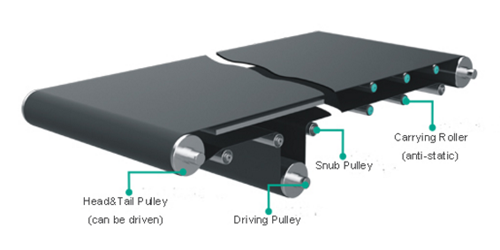

In the right area of the Damon Industry intelligent rollers, there is the newly released belt conveyor pulley, which could be widely used in tobacco, clothing, express mail service and logistics distribution.

Mr. Weibin cao has explained to the journalist in details that this roller has adopted the new welding technology. In the traditional welding process, the spindle nose and shrouding is connected by the welding rod, which covers the surface of the excircle. It mainly uses the ordinary gas protection in welding. Also a third type of material has been added during the process of welding, so it has increased the risk of mixing the impurities, also the product stability is not so good. While in the new welding technology, the spindle nose and shrouding is connected by the melting materials after high-speed revolution and extrusion. So it has good penetration. Also because it adopts the automatic friction welder, the products have high stability and efficiency. ‘For example, diameter of axleφ45mm, weld bead height 6mm, compared with the traditional welding, friction welding’s ultimate bearing capacity has been improved almost 65%.’ Mr. Weibin Cao said, ‘Adopting the new technology could save the material and lower the roller’s weight, so that the aim of saving energy and reducing consumption has been achieved. Additionally, it has reduced the harmful gas, which could avoid the impact on welder’s health and meet the national strict requirements for environmental protection.’

Damon Industry is quite strict for each product, continuous innovation is an important support for its sustainable development. ‘For example, when the new belt roller was developing, Damon Industry had set up a new department, which consists of more than 20 people. Also it purchased a newly welding equipment in its thousands of square meters production workshop.’ With regard to the input in Damon Industry’s product innovation, Mr. Weibin Cao is very proud, ‘Each year, 3% of Damon Industry’s sales volume will be invested in technology and innovation. Although the technology of rollers has tended to be mature, we are still working to seek the possibility of improving user’s work efficiency.’ From material to technology, from structure to application, from work flow to technical support, Damon is taking all the innovation actions to improve the product added value. In the meantime, it focuses on solutions to specific problems and business needs in order to set out from customers’ needs and to create greater competitiveness for their logistic system.

Now users’ demand for intelligent logistics and supply chain optimization is gradually increasing. ‘With regard to the increasing demand for the logistics equipments in the supply chain optimization, Damon Industry has not adopted a radical way, we always believe that to seek improvement in stability and to make a solid basic skills is the best way of development.’ Mr. Weibin Cao said, so in customer retaining, product optimization and new products development, Damon Industry has its specific plans and strategies, ‘For example, currently mobile service has become the mainstream, so Damon Industry has launched the model selection APP accordingly, which is convenient for customers to operate in the mobile phone.’ Facing the fast-change markets, Damon Industry’s top priority is to make products to adapt to the application changes that caused by environmental changes as soon as possible.