Europe

中文

English

Europe

Welcome to Damon Industry Website

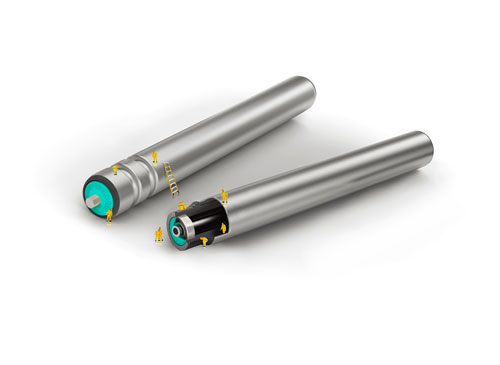

With the rapid development of fields like E-commerce, express delivery and logistics and the popularization of automated logistics, roller conveyors have been used widely. Roller conveyors have already evolved from a niche product processed by a machine to a common and standardized industry product manufactured on an assembly line.

Steel is the most common material out of which the roller tube is made of and the rule stands for almost 90% of the rollers. The steel tube is the main component of the roller and also the load bearer, this is why the steel tube’s quality influences directly the product’s quality.

Firstly, let’s talk about the reason why the steel tube roller is welded, not seamless.

1. The welded tube is made of a steel strip of a certain thickness that undergoes the process of high frequency welding. It has a fairly good strength and it is widely used in several industries of non-pressure pipeline. At the same time, because the steel strip’s thickness is uniform, the tube reaches a dynamic and static equilibrium, so it will not curl back.

2. The seamless tube, as the name implies, it presents no holes and by undergoing the process of cold-drawing, tubes of different diameters are produced to be used in various pressure pipeline industries. Due to the production process, the wall thickness of the seamless tube is not uniform; in order for a seamless tube with uniform wall thickness to be produced, the inner and outer diameters need cold-drawing, a process which greatly increases the costs.

Therefore, the high frequency welded tube is the most suitable for the roller conveyor. Welded steel tubes used for roller conveyors at Zhejiang Damon Industry are of high quality and meet specific standards, such as: GB/T 13793-2008 "Straight Seam Electrically Welded Steel Pipes"

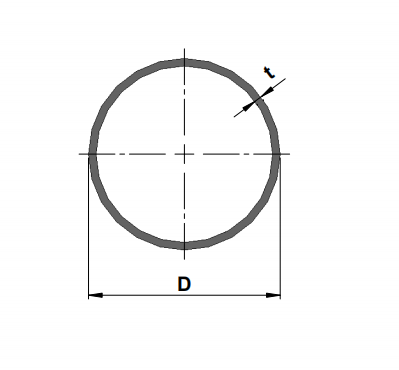

Secondly, let’s talk about the steel tube’s wall thickness:

A roller tube’s wall thickness is important for maintaining the tube’s strength and also, for absorbing the shock of the transported goods.

If your conveyor transports card boxes or plastic containers weighing less than 30 kg, the impact force is not strong, so a wall thickness of 1.5 mm is recommended. If your conveyor transports a medium-sized load of less than 500 kg, it is recommended to use a tube with a wall thickness of 2 mm; if your conveyor transports a heavier pallet or metal goods, you need to use a tube with a wall thickness of 3 mm or more.

Lastly, we will talk about materials used for tubes that does not rust:

The most common type of steel used for the steel tubes is stainless steel 304. Its advantages and disadvantages are as follows:

Because they serve food industries and pharmaceutical industries or they are placed in humid environments, costs are relatively high.

Currently, there are some customers that use this kind of tubes for aesthetic reasons in environments that do not impose such high hygienic requirements as the pharmaceutical industry or that are not humid, e.g. the fashion industry. For such an environment, Zhejiang Damon Industry recommends the tubes made of J4-200 stainless steel, its features as follows:

This material will not rust in an indoor environment, it has a good appearance and its costs are not as high as of the 304 ones. We like the right ones, but also the cheap ones.

As a professional manufacturer focusing on roller conveyors for more than 15 years, Zhejiang Damon Industry is very happy to share our expertise and experience with you, so to be able to improve competitiveness.